OEM/ODM Service

for Precision wire terminal and cable connector

FPC Connector Factory SINCE 1994

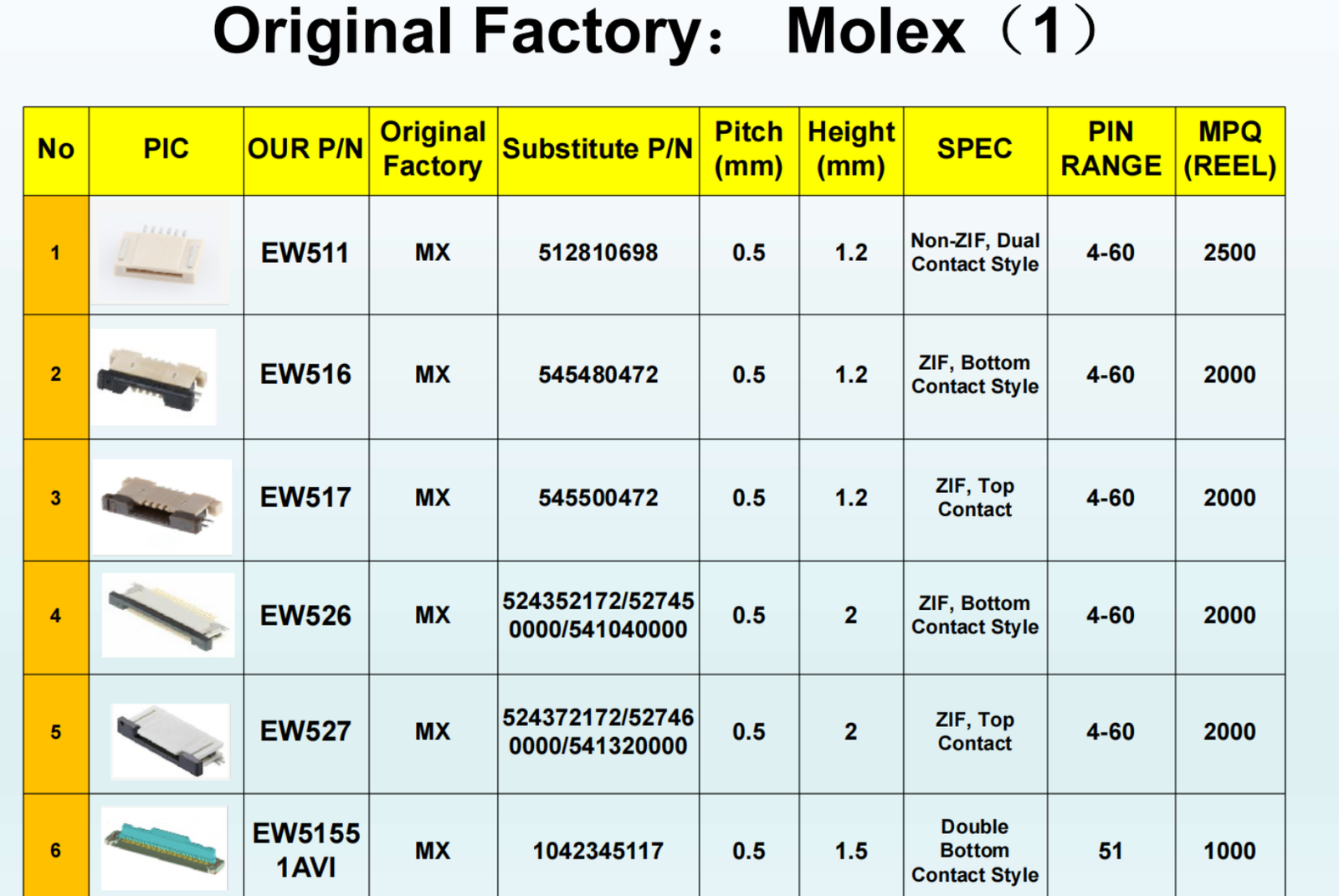

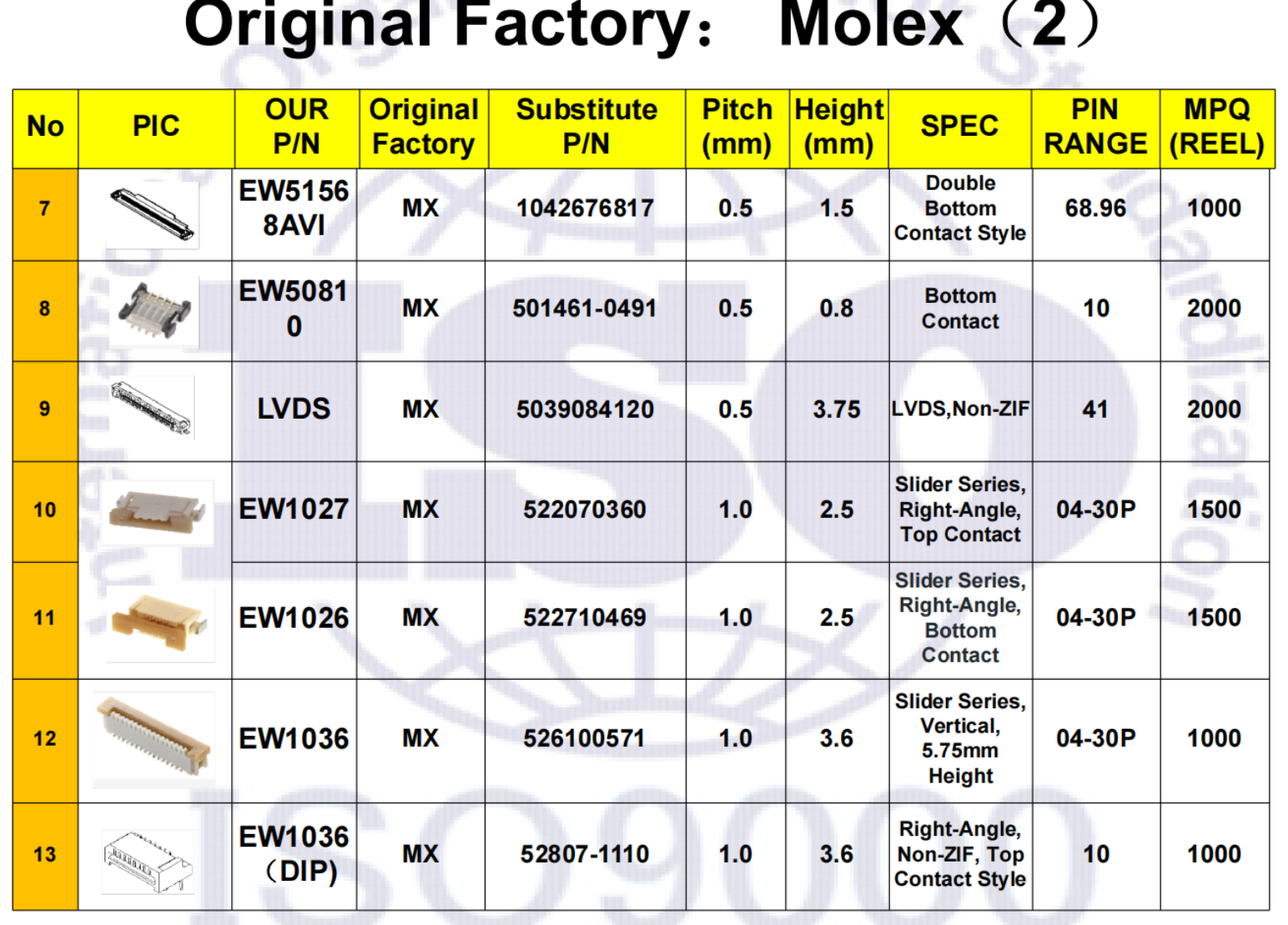

Alternative connectors Molex,Hirose,Omron

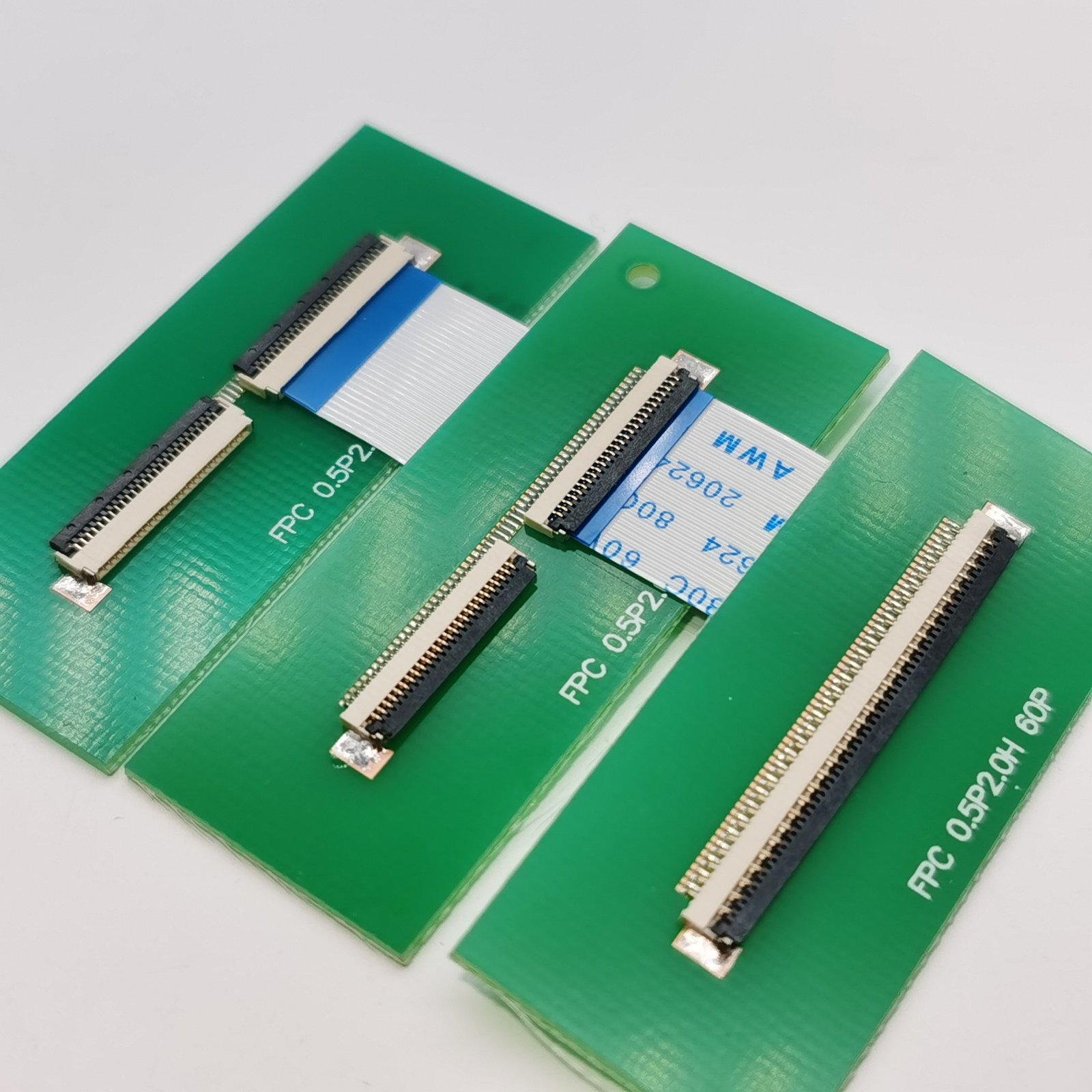

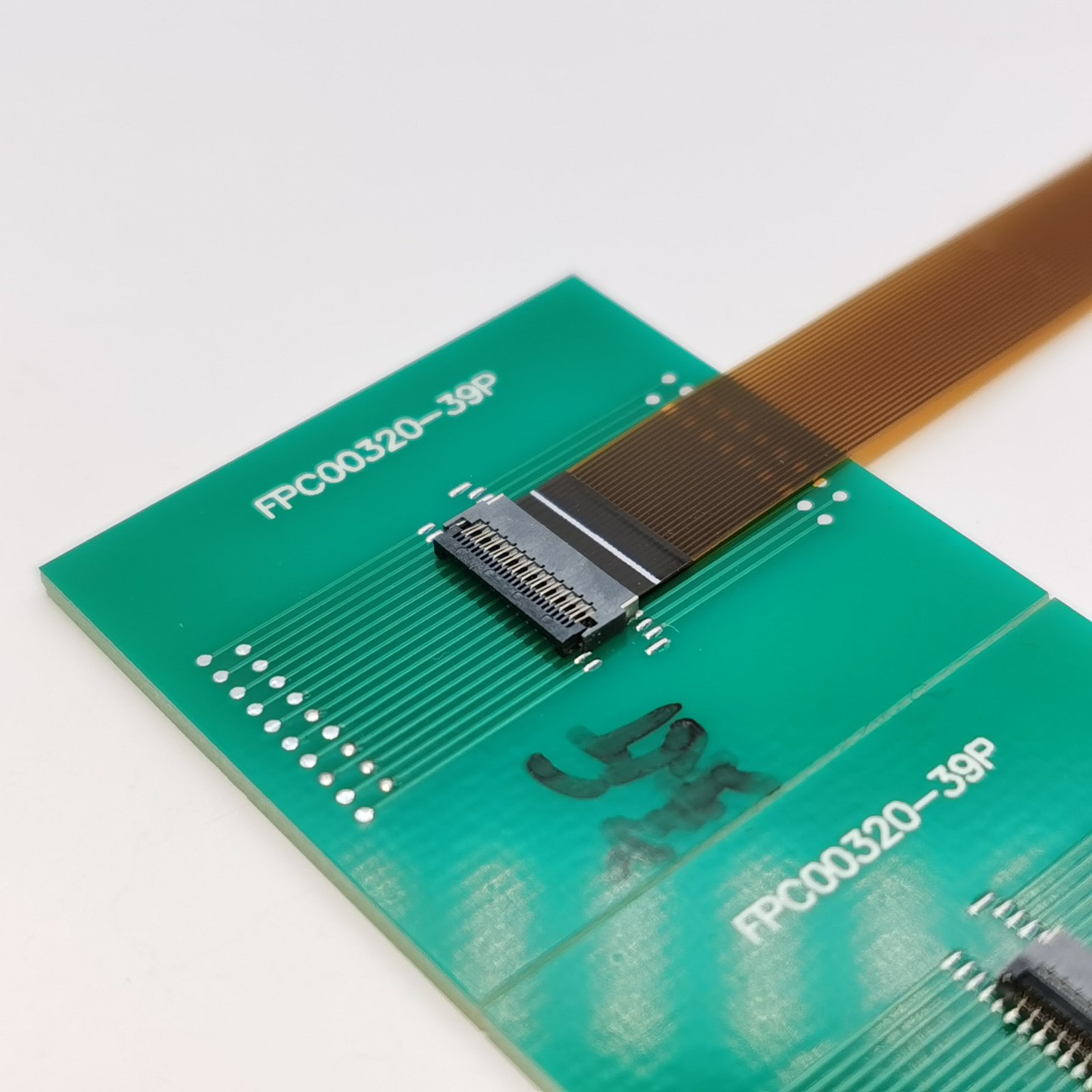

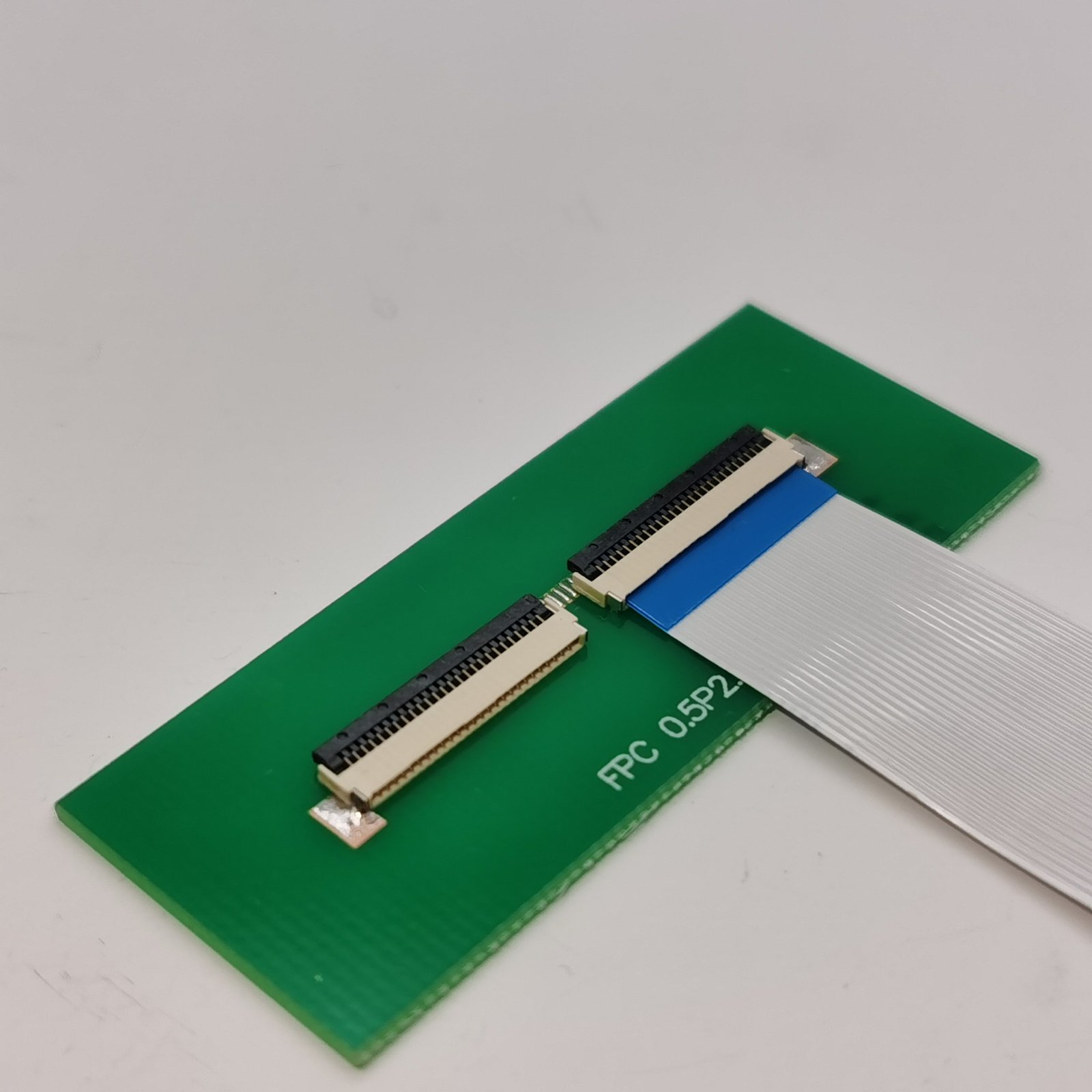

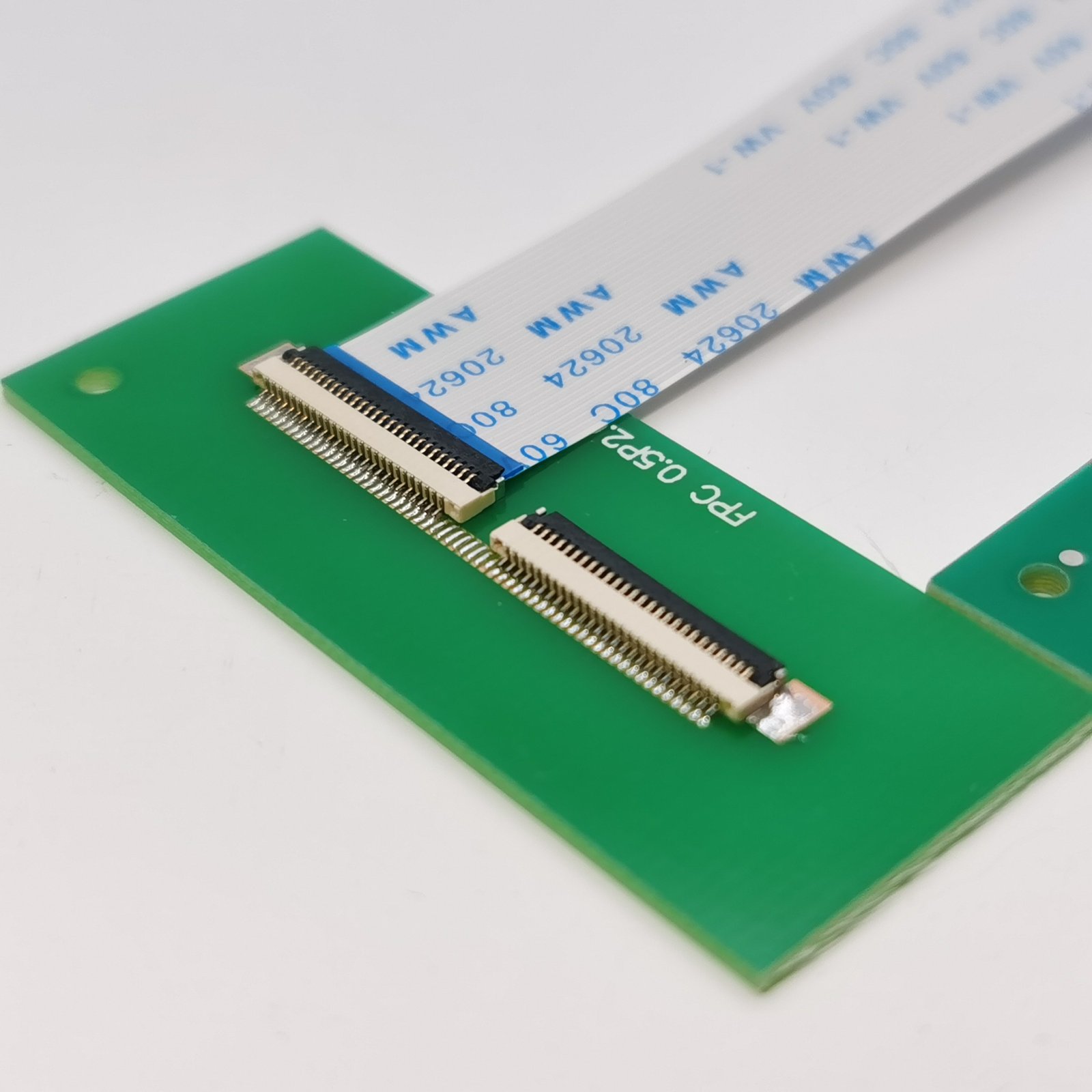

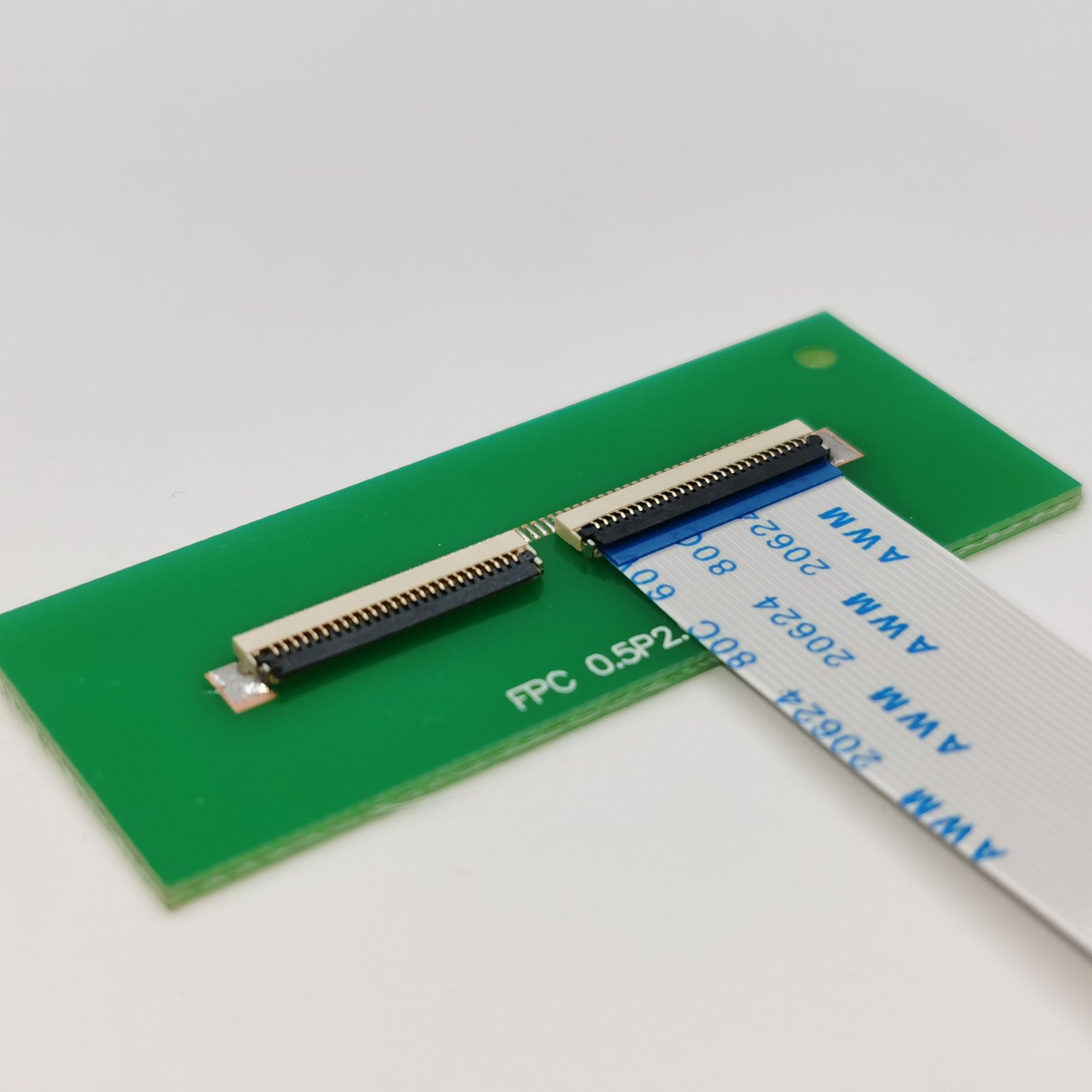

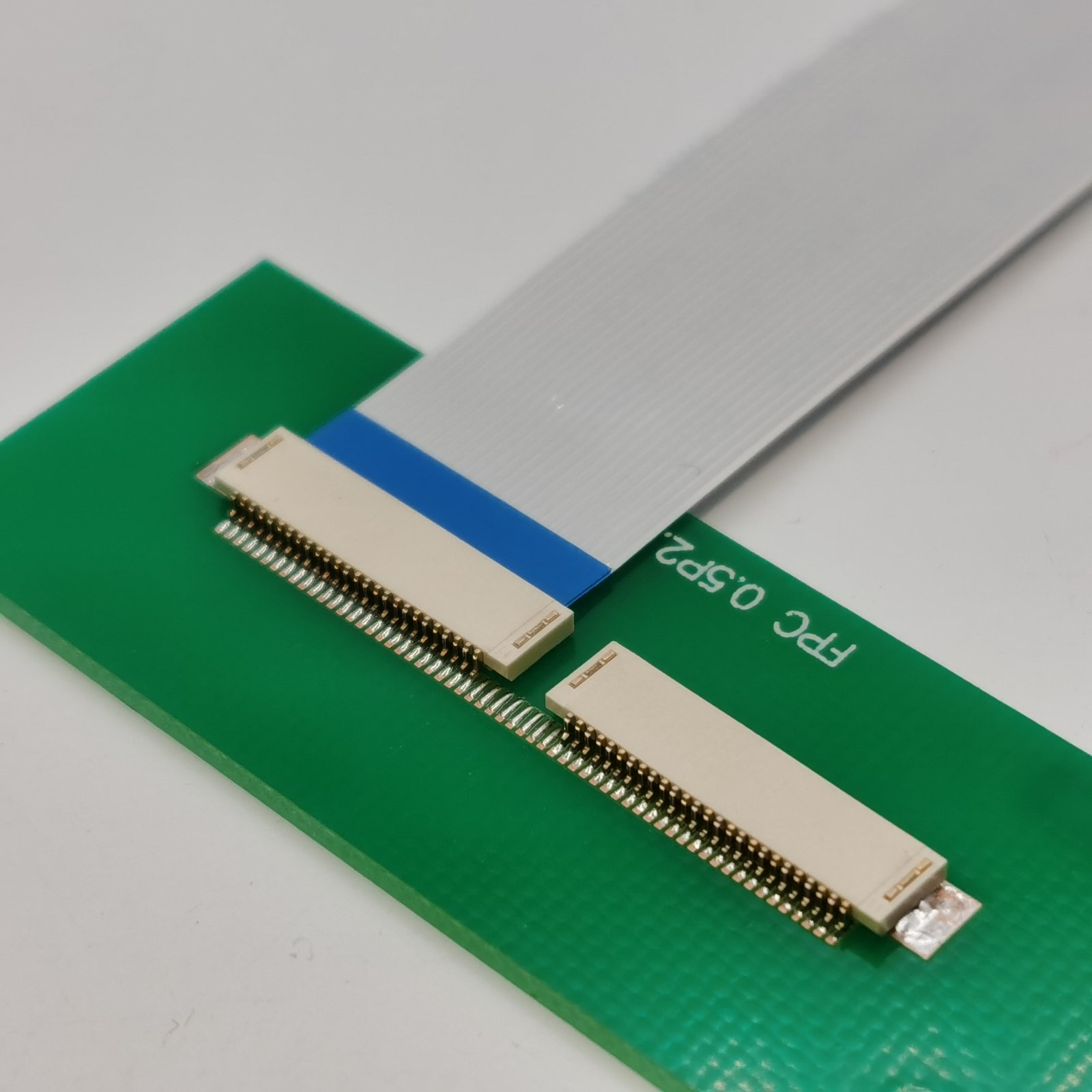

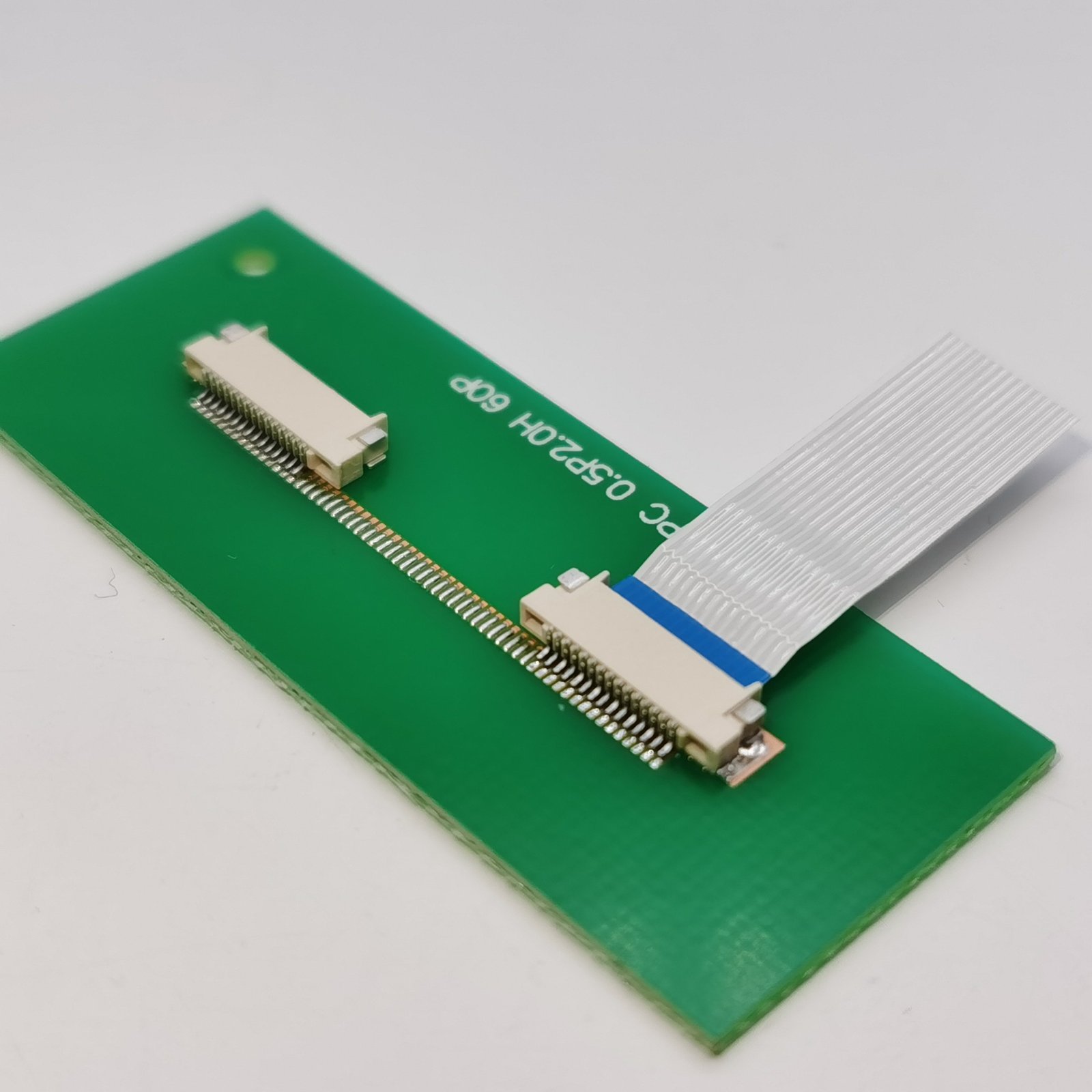

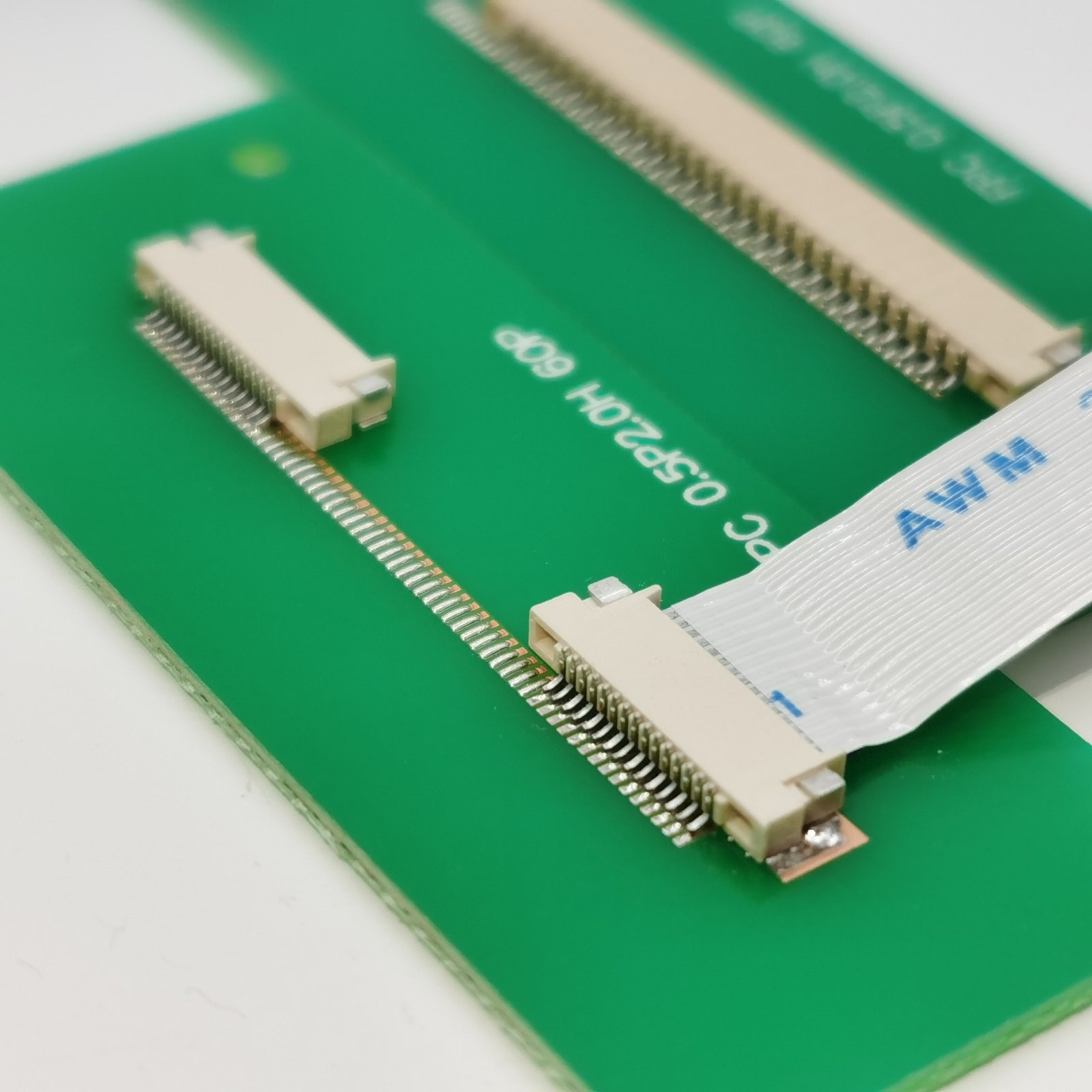

Products Show

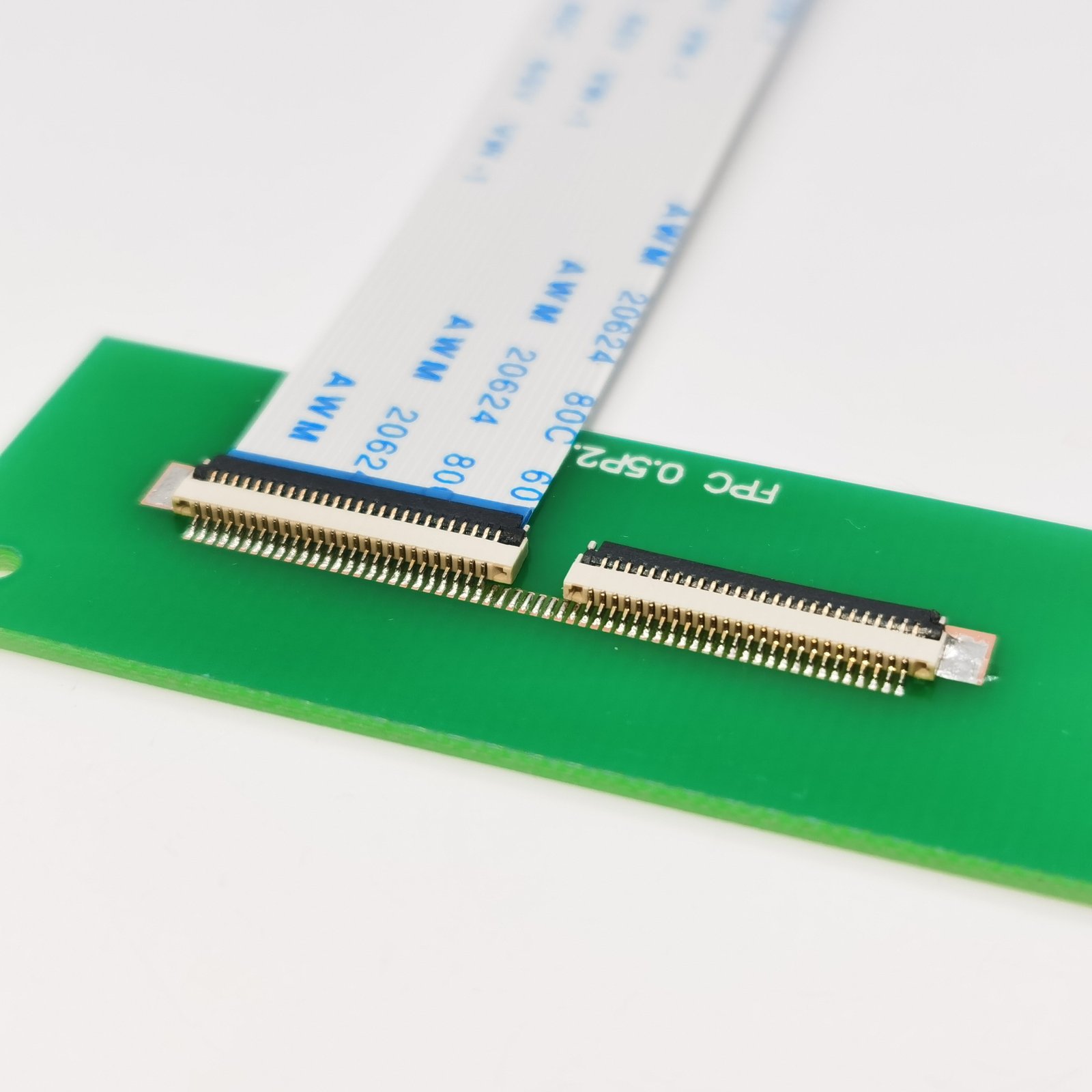

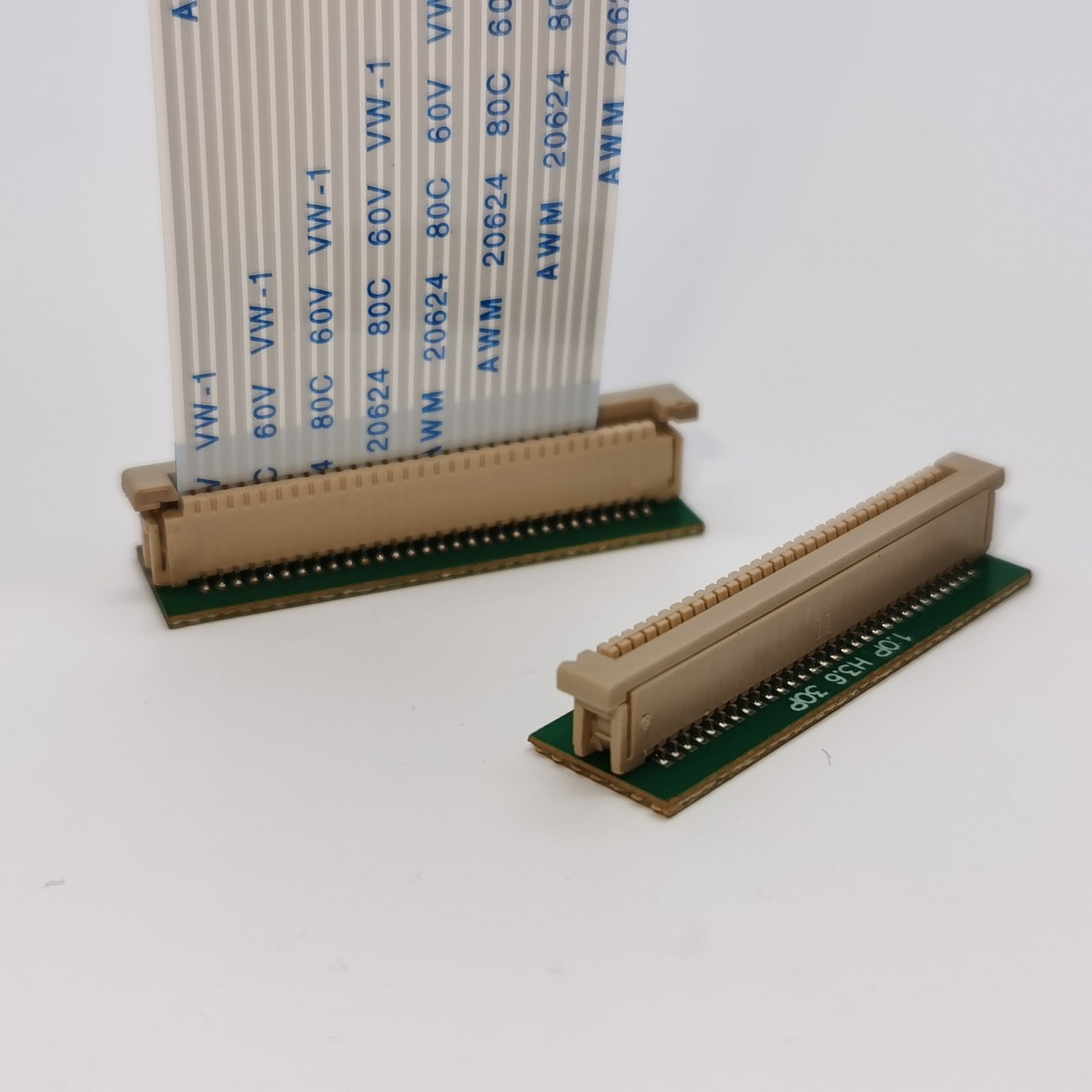

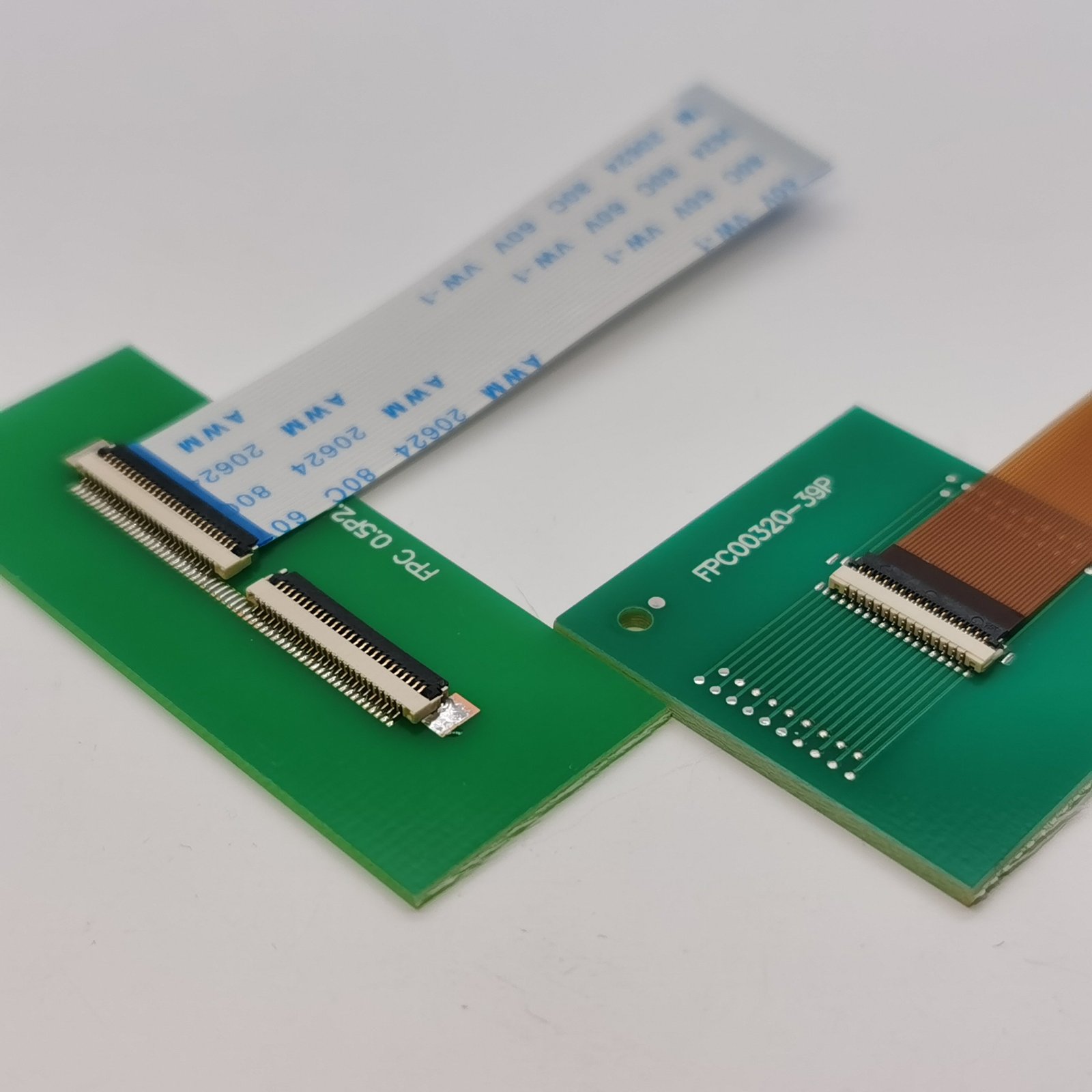

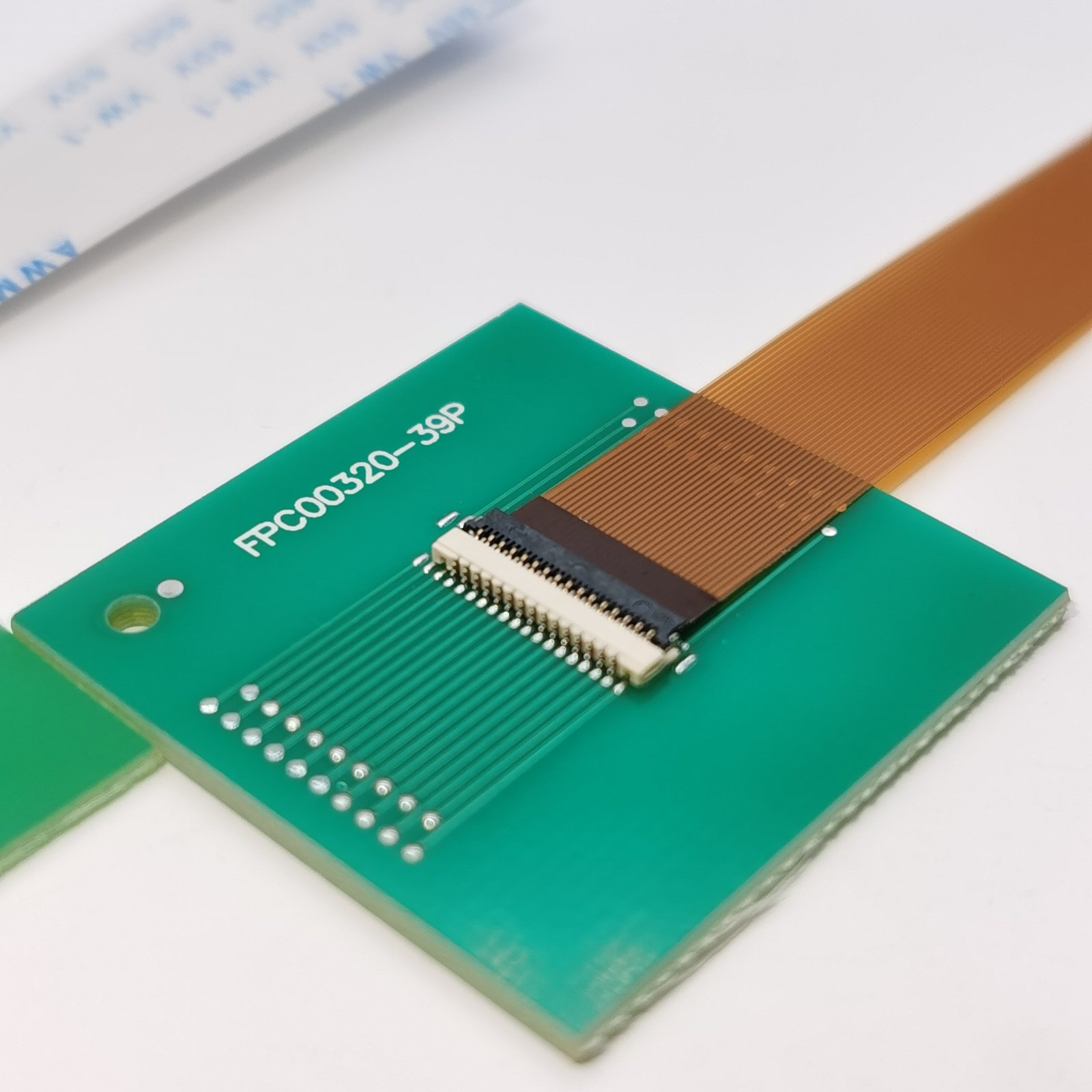

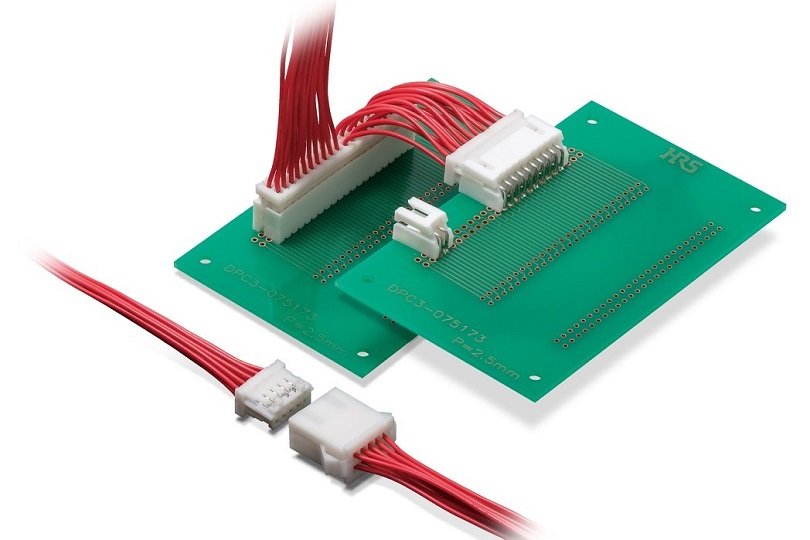

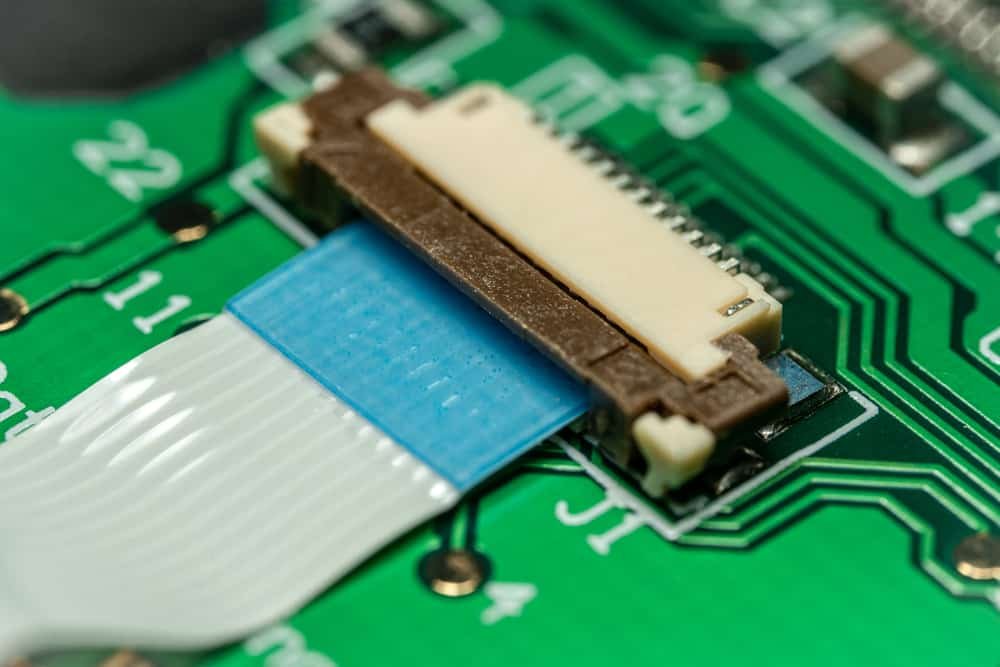

Main products: FPC/FFC Connector, Board to Board Connector, Wire to Board Connector

Get the Full Products list Now!

Hot-sale Connectors!

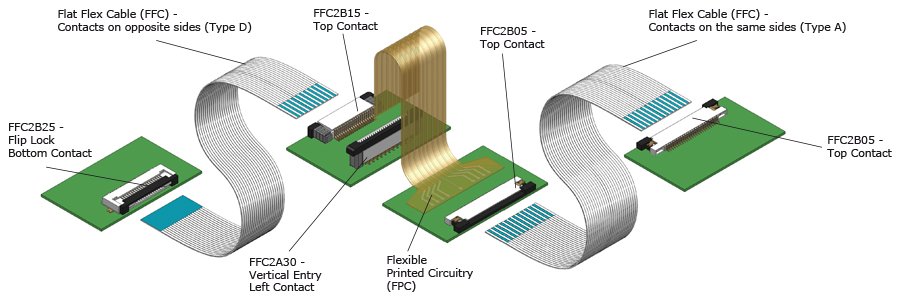

Connectors Classification

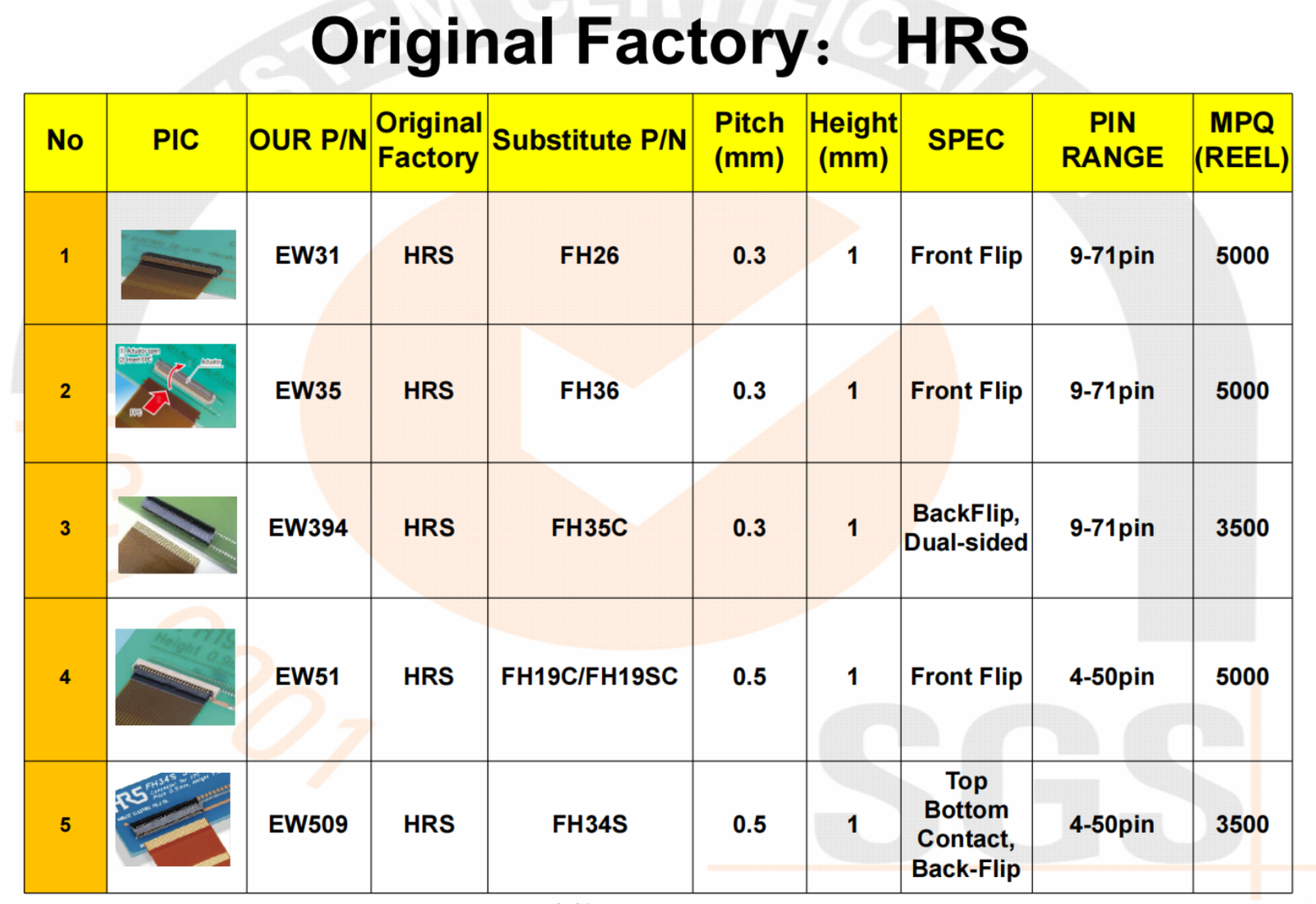

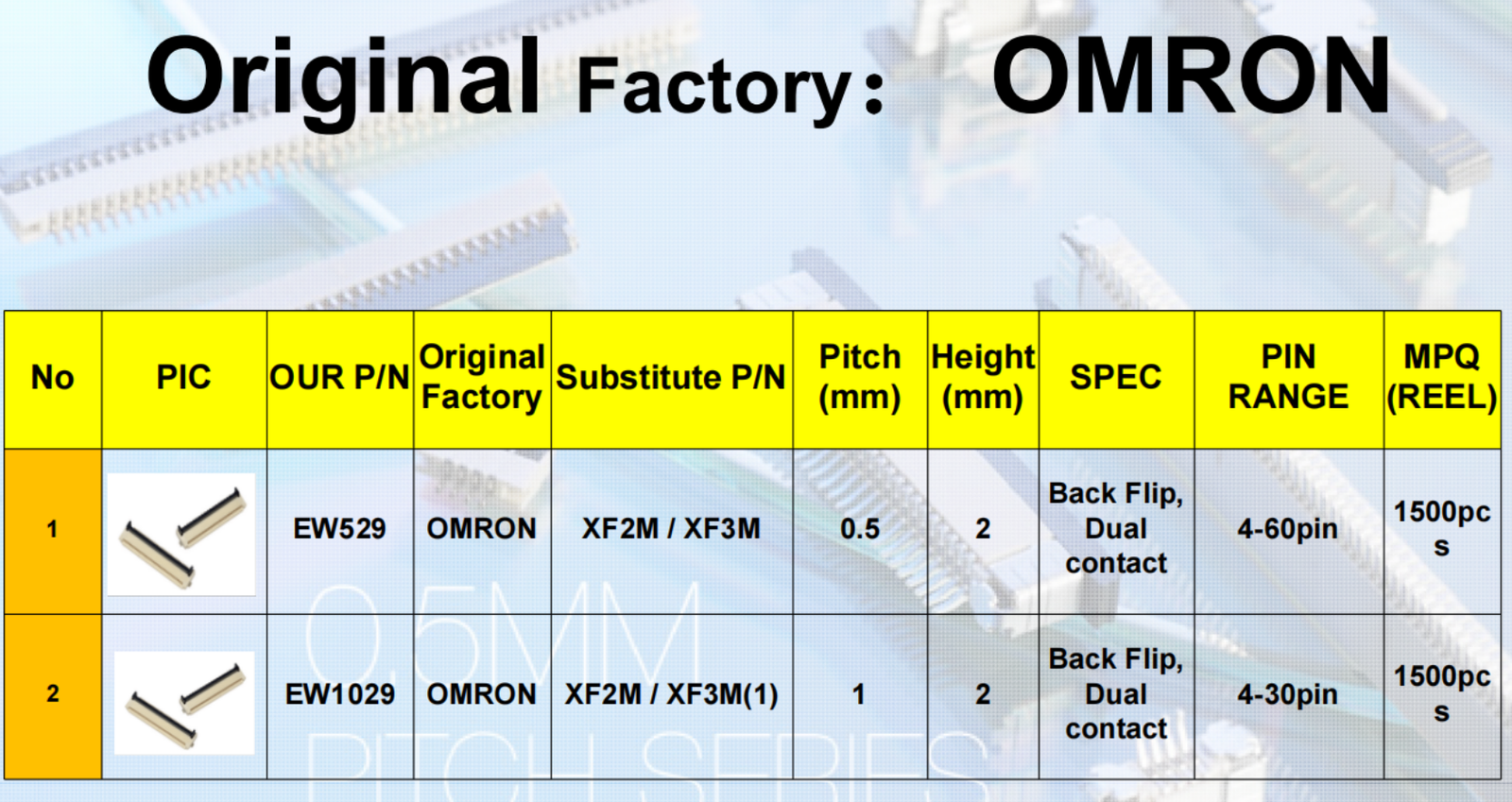

According to famous Original factory Hirose, molex, Jst, Omron, So far we have finished Connectors to replace them.

There are also relevant drawings and specifications, please contact us directly

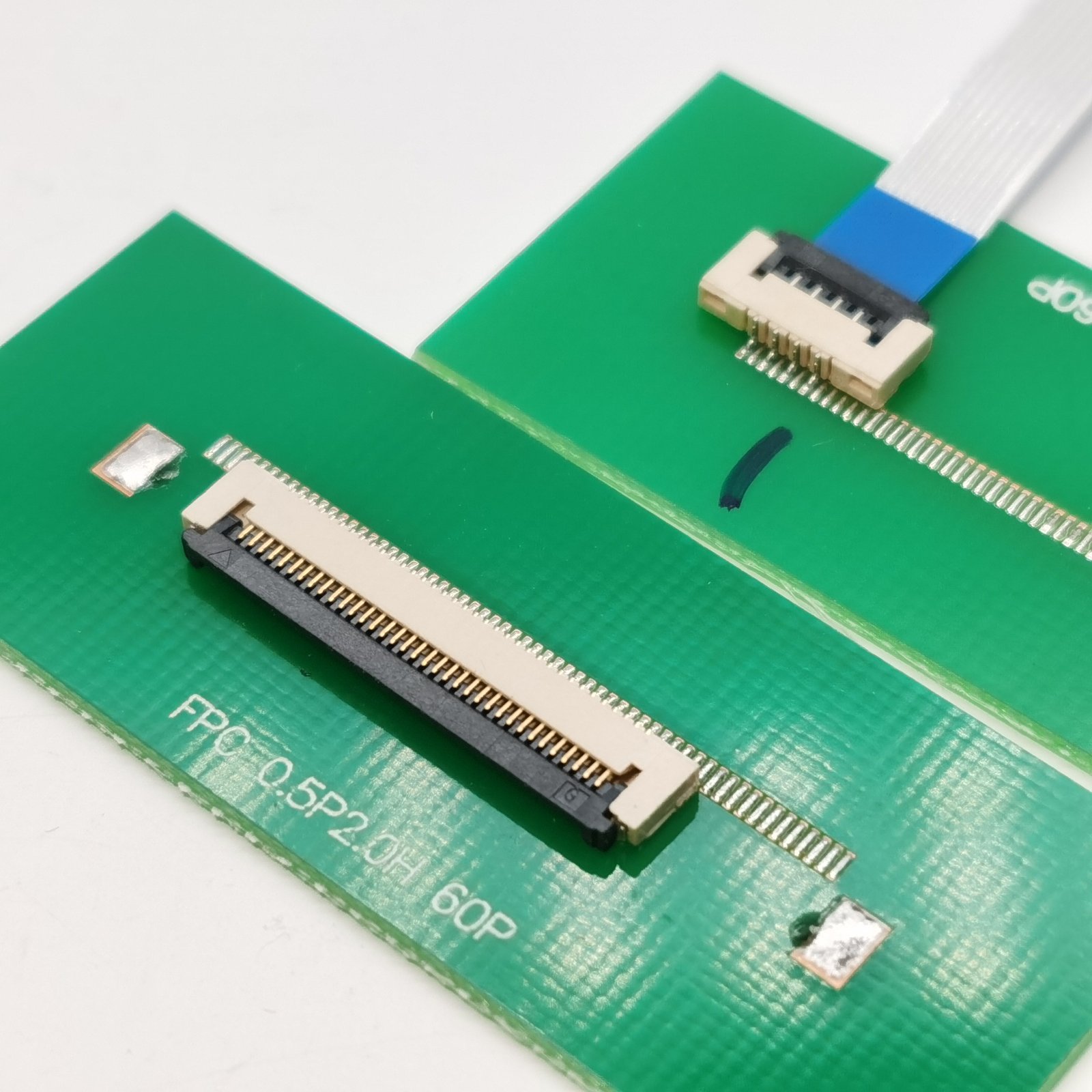

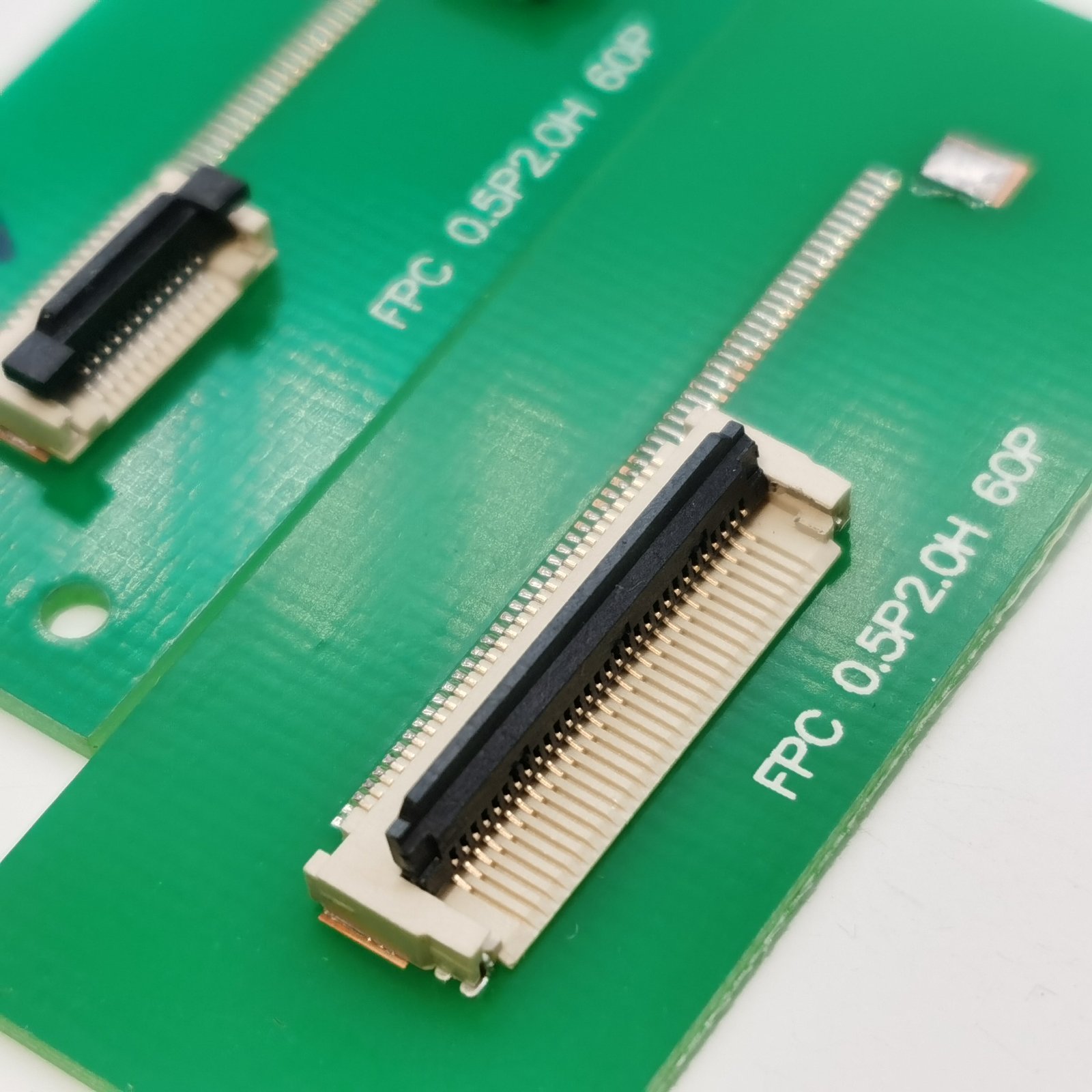

According to the Pitch, we will show main Pitch: 0.3mm, 0.5mm, 0.8mm,1.0mm

According to the type, we will show main types: ZIF, NON-ZIF

Do you need the datasheet?

Because there are many types, we only show a part of the horizontal connector, and the vertical connector is not shown. If you need a full catalogue,please contact us directly.

Choosing our products is equivalent to choosing an excellent technical team

Our FPC connectors are designed to meet a wide range of requirements, ensuring versatility and reliability in various applications. Here are the key advantages of our products:

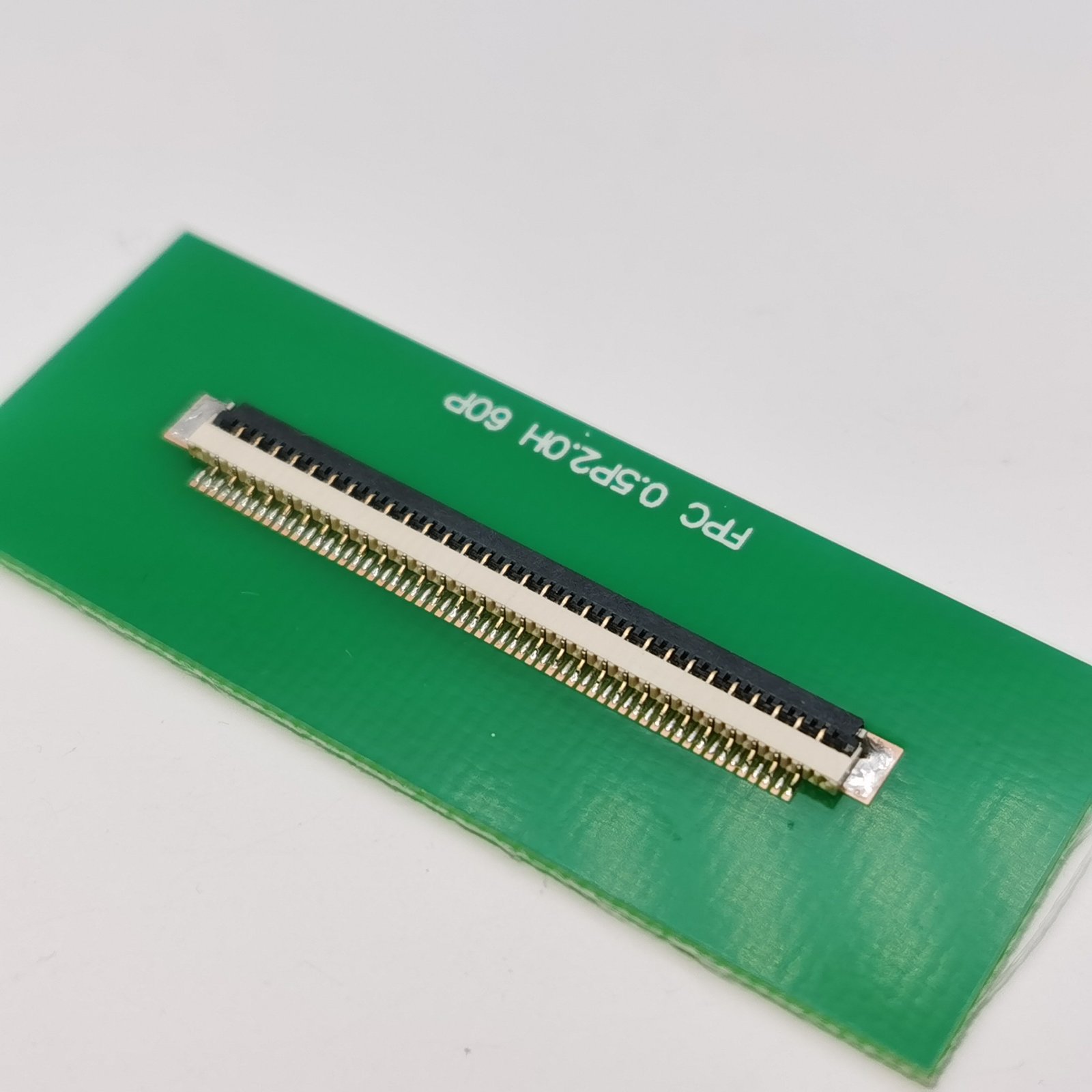

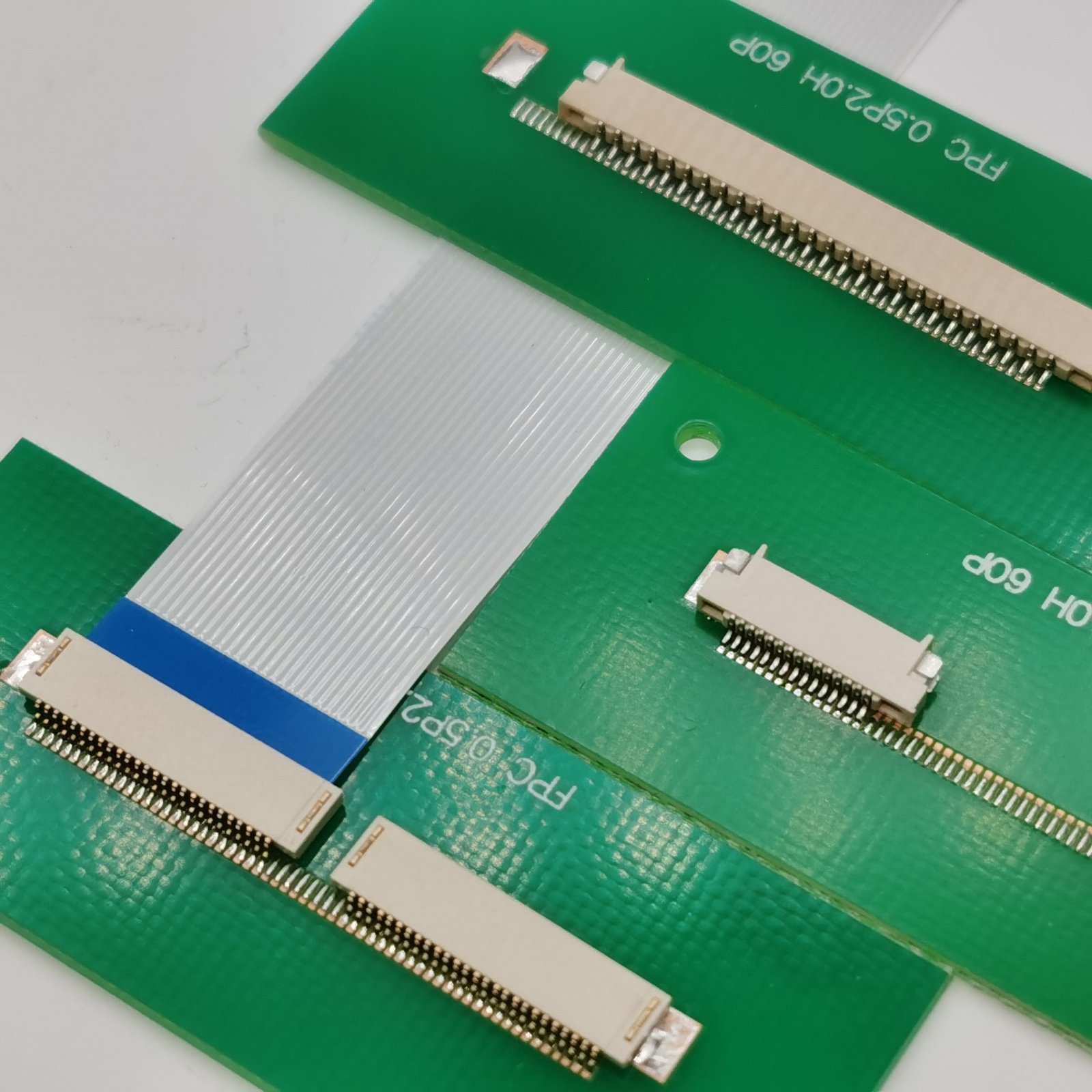

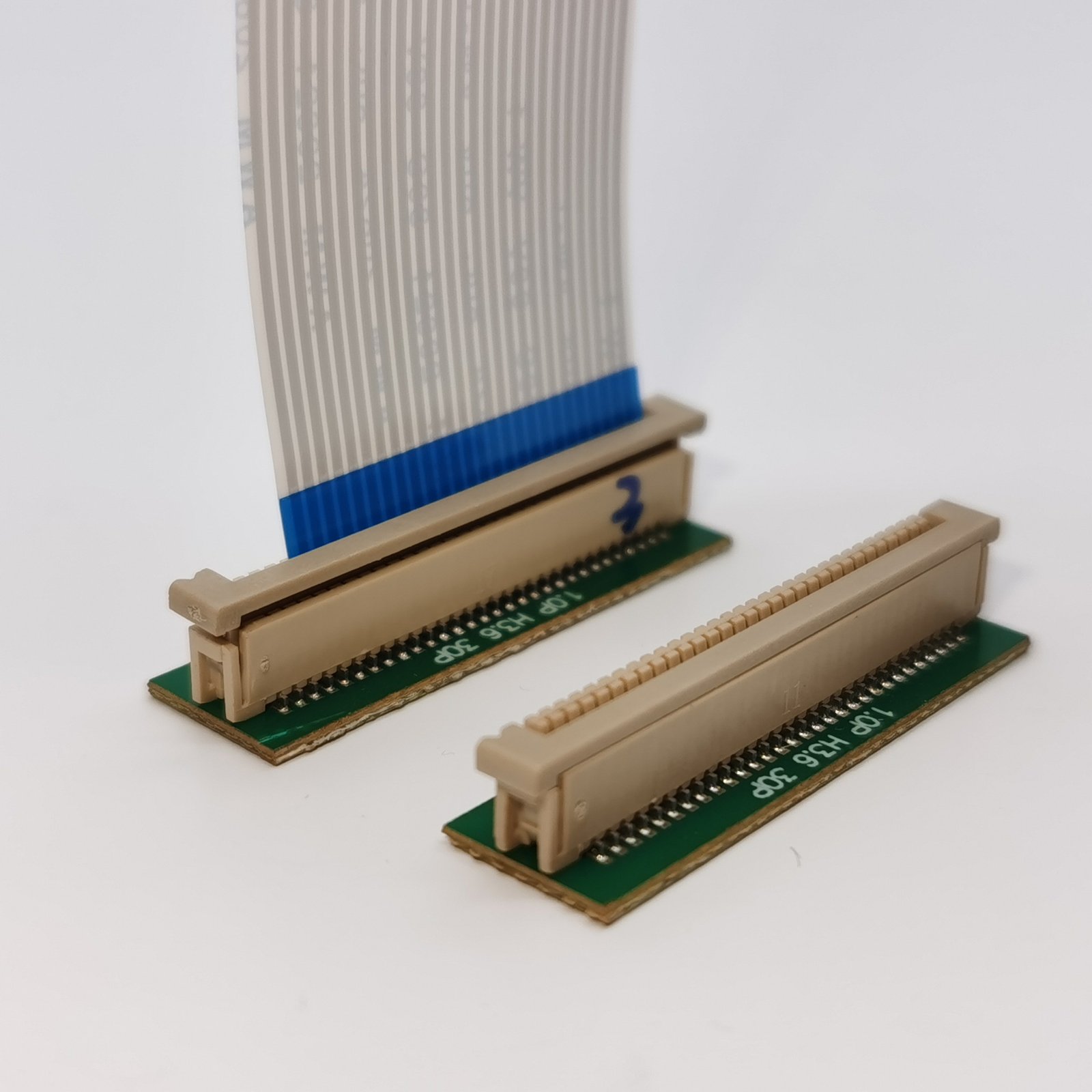

Pitch Range: Available in 0.3mm, 0.5mm, 0.8mm, and 1.0mm pitch sizes.

Height Options: Heights include 1.0mm, 1.2mm, 1.5mm, 2.0mm, and 2.5mm.

Pin Count: Offering a range from 4 to 80, and up to 96 pins.

Connector Types: Includes ZIF (Zero Insertion Force) and NON-ZIF types.

Contact Points: Options for top contact, bottom contact, and dual contact.

Mounting Styles: Available in DIP and SMT (Surface-Mount Technology) types.

Plastic Parts: Made from high-temperature, environmentally-friendly materials such as LCP, Nylon, and 9T.

Metal Terminals: Use of brass or phosphor bronze, chosen based on product requirements.

Plating: Phosphor bronze plated with tin or gold to ensure excellent conductivity and corrosion resistance.

Material Performance: Thorough understanding and selection of materials to ensure product stability.

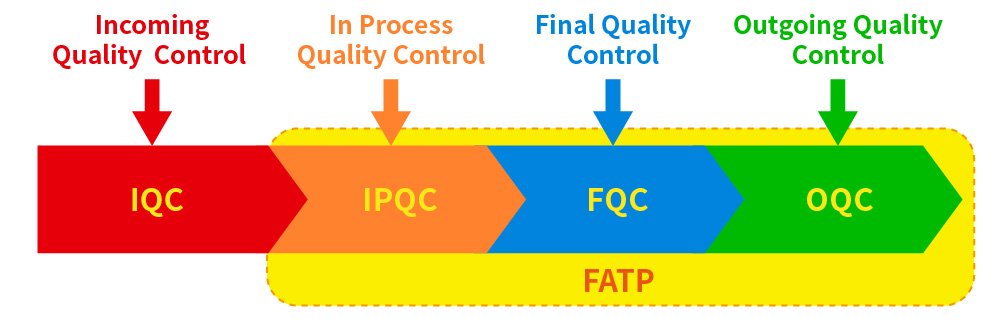

Inspection Standards: Adherence to strict inspection standards including IQC (Incoming Quality Control), IPQC (In-Process Quality Control), FQC (Final Quality Control), and OQC (Outgoing Quality Control).

Certifications: Our factory is ISO9001 certified, and our products have SGS certification, ensuring compliance with international quality standards.

We offer samples to help clients evaluate our products before making bulk orders.

Our sales operations include full import and export capabilities, ensuring smooth international transactions.

Expert Team: Dedicated team to provide professional customer service and technical support.

Comprehensive Service: Assistance with issues during SMT processing or assembly, ensuring minimal disruption and quick resolution of any problems.

Experience: With over 20 years in the electronic connector industry, we have encountered and resolved numerous technical challenges, providing reliable support to our clients.

Our FPC connectors are used in products manufactured by industry giants like Foxconn and Amazon. For instance, our connectors are used in Amazon’s Ring video doorbells, which are then assembled by Foxconn and distributed globally.

By choosing our FPC connectors, you are not only selecting a reliable product but also gaining a dedicated and professional team to support your technical needs and ensure your success in the market.

Application Cases of Connectors

Our connectors are generally used in the interior of electronic products, so we will anatomize electronic products to show you how widely used FPC connectors are

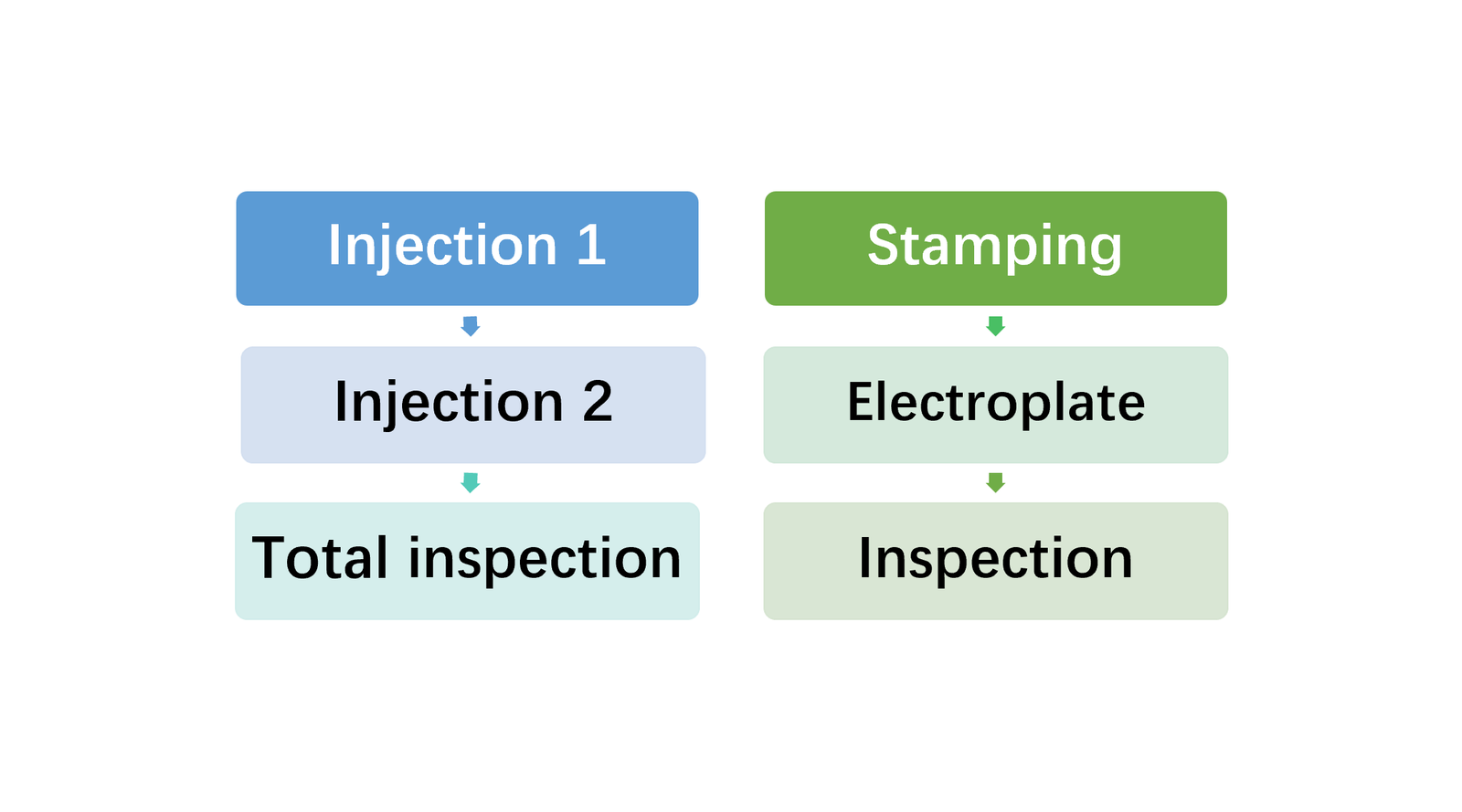

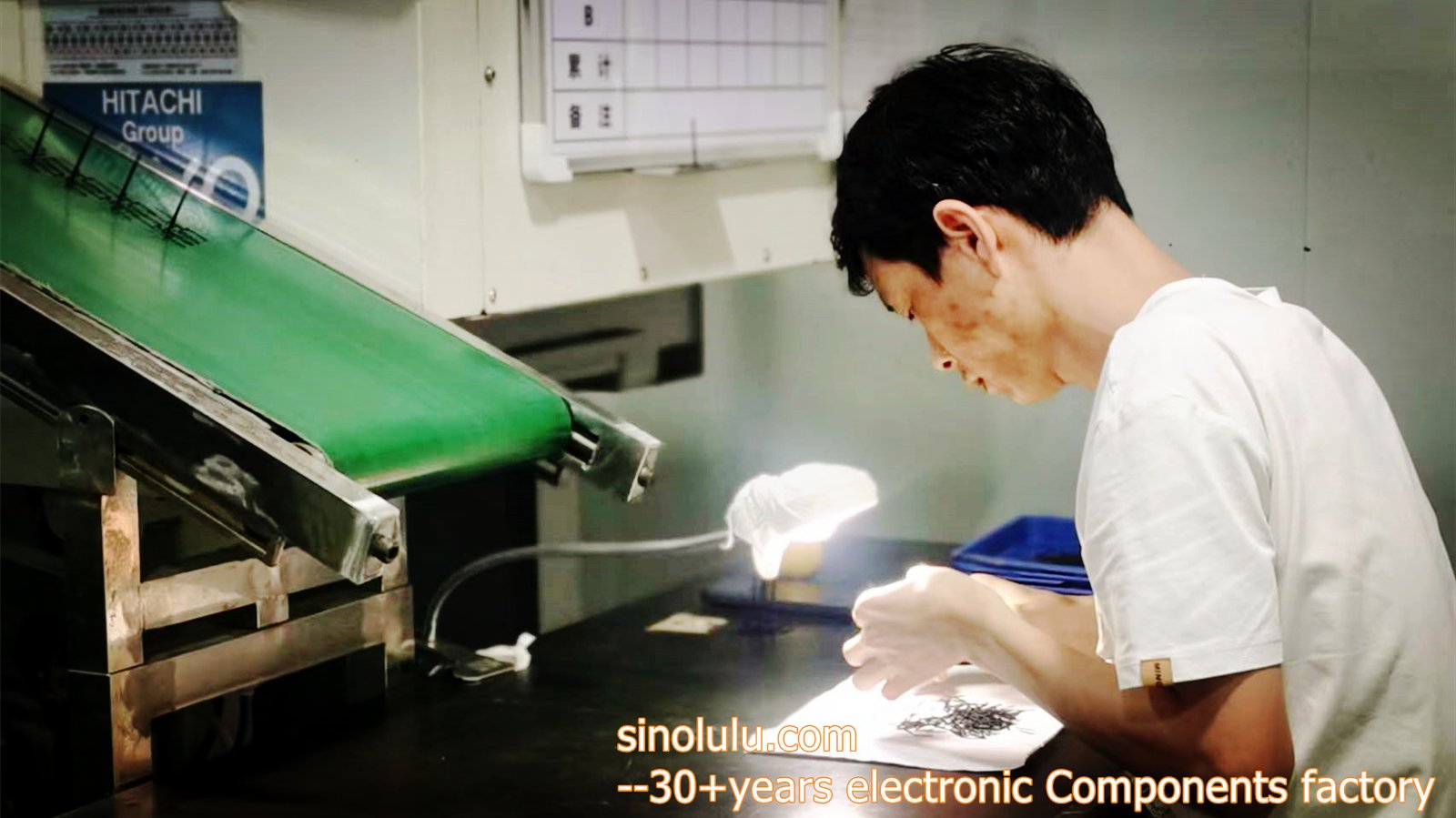

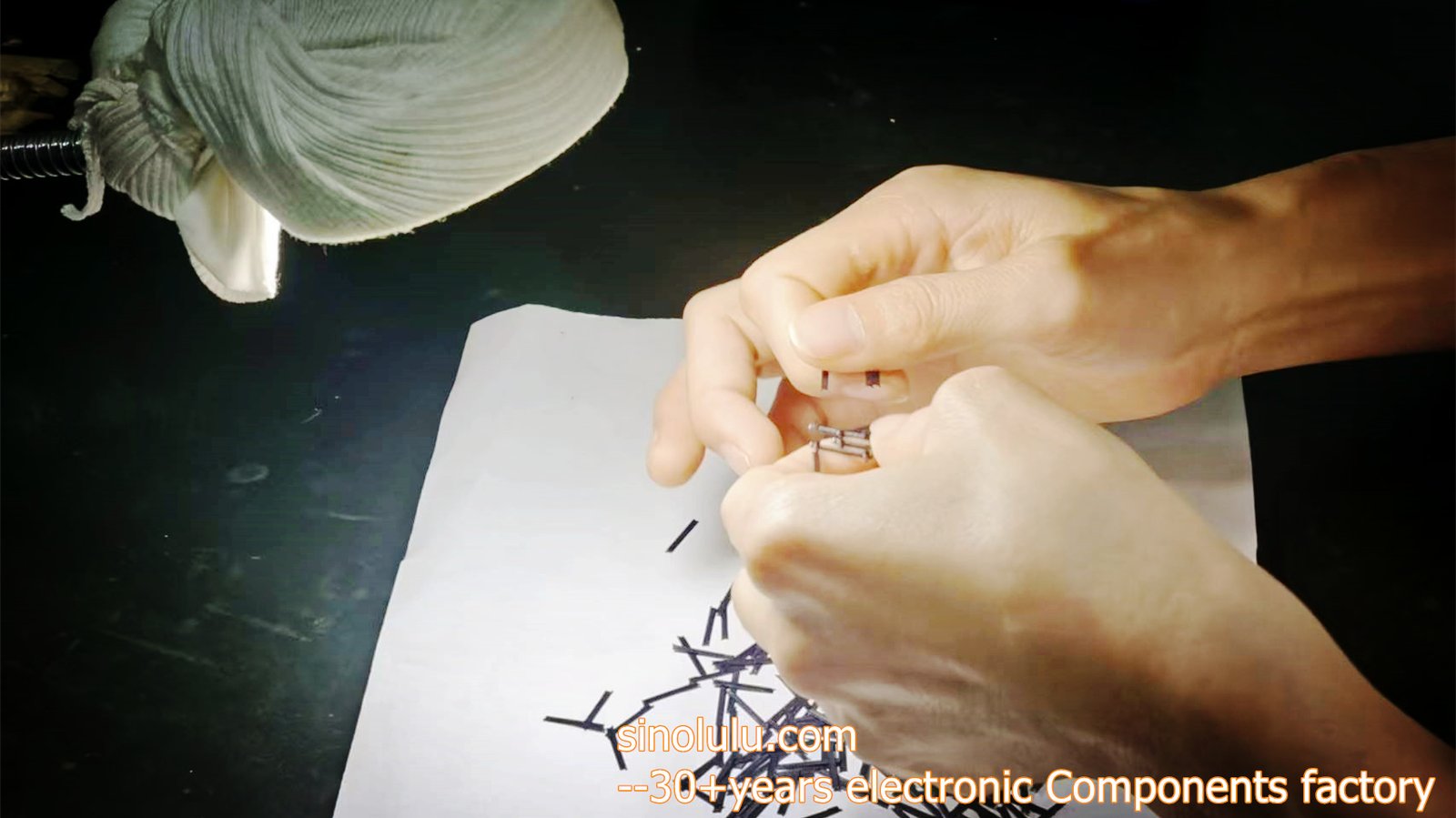

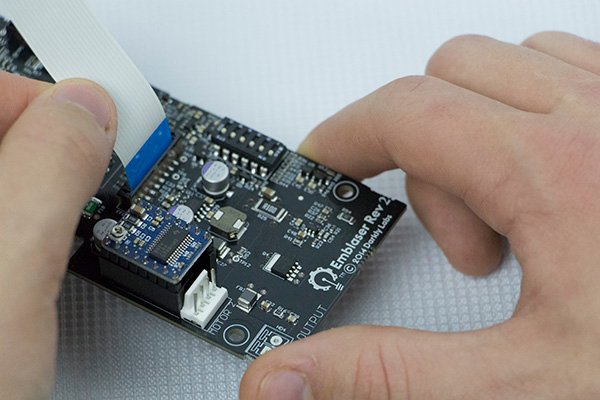

How to Produce it

Learn more about the Production,Learn more about Sinolulu

From plastic molding+metal stampling+electroplating,

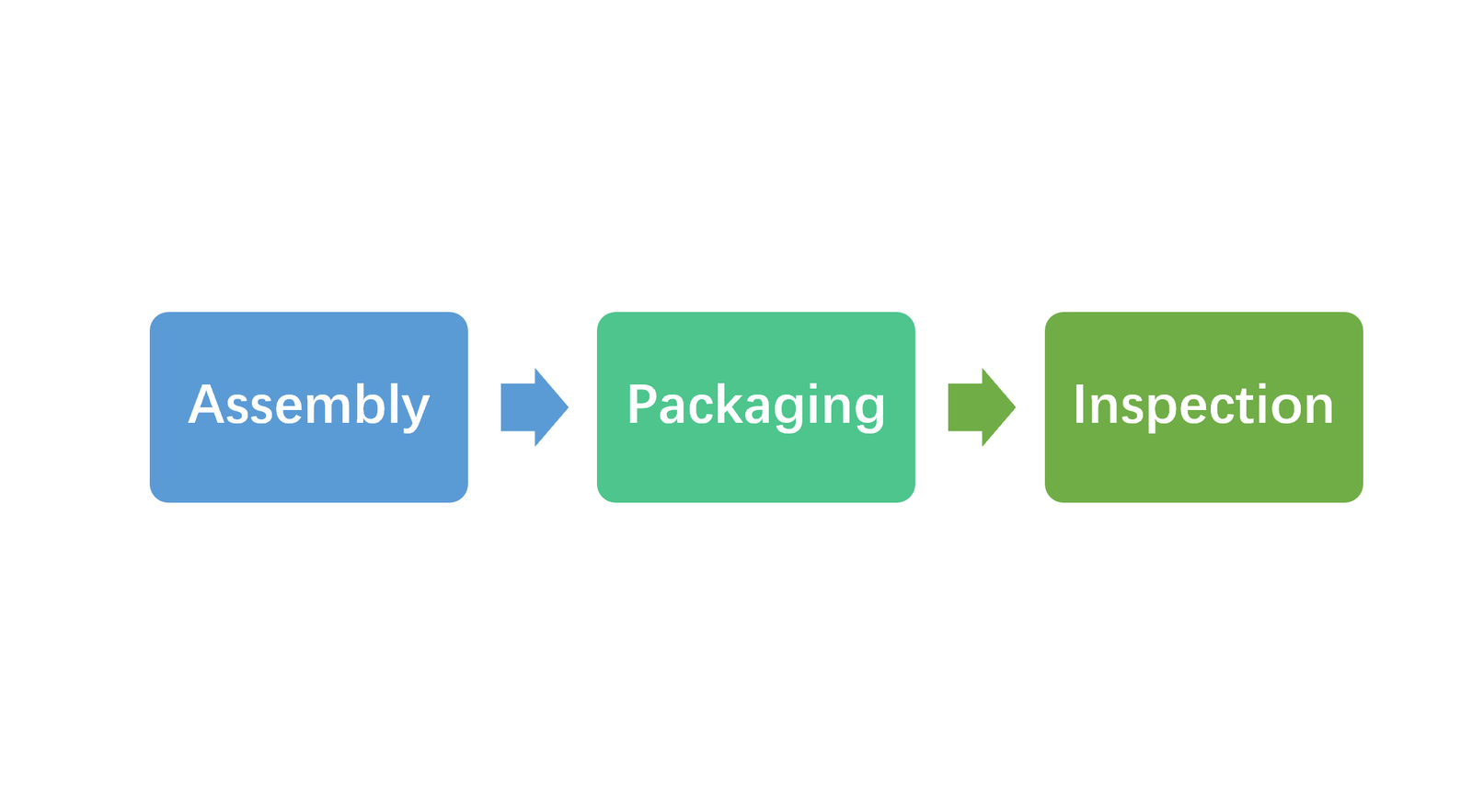

to Assemble the parts to finished connectors. Show some parts of productions here.

Get more info about the production!

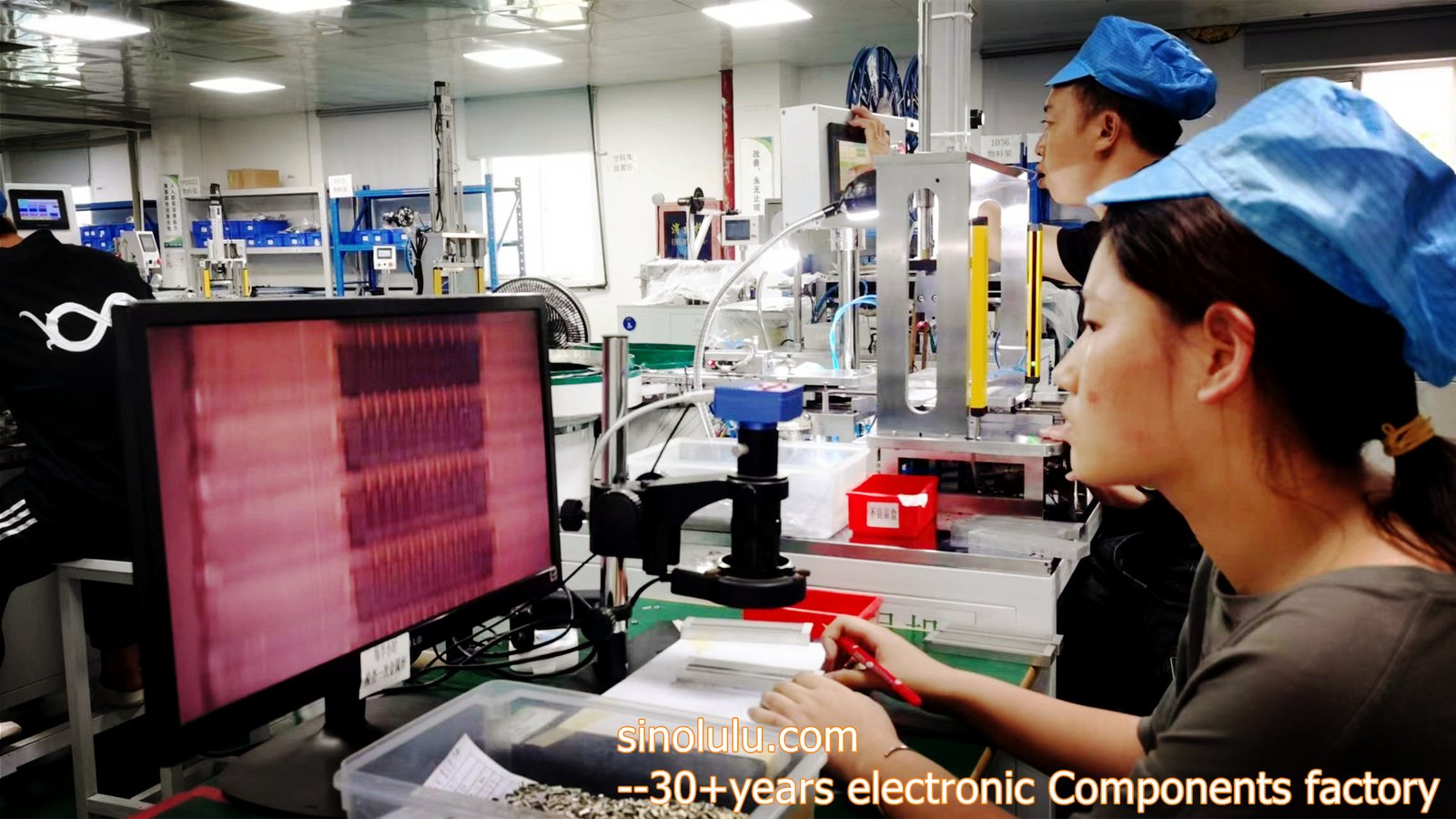

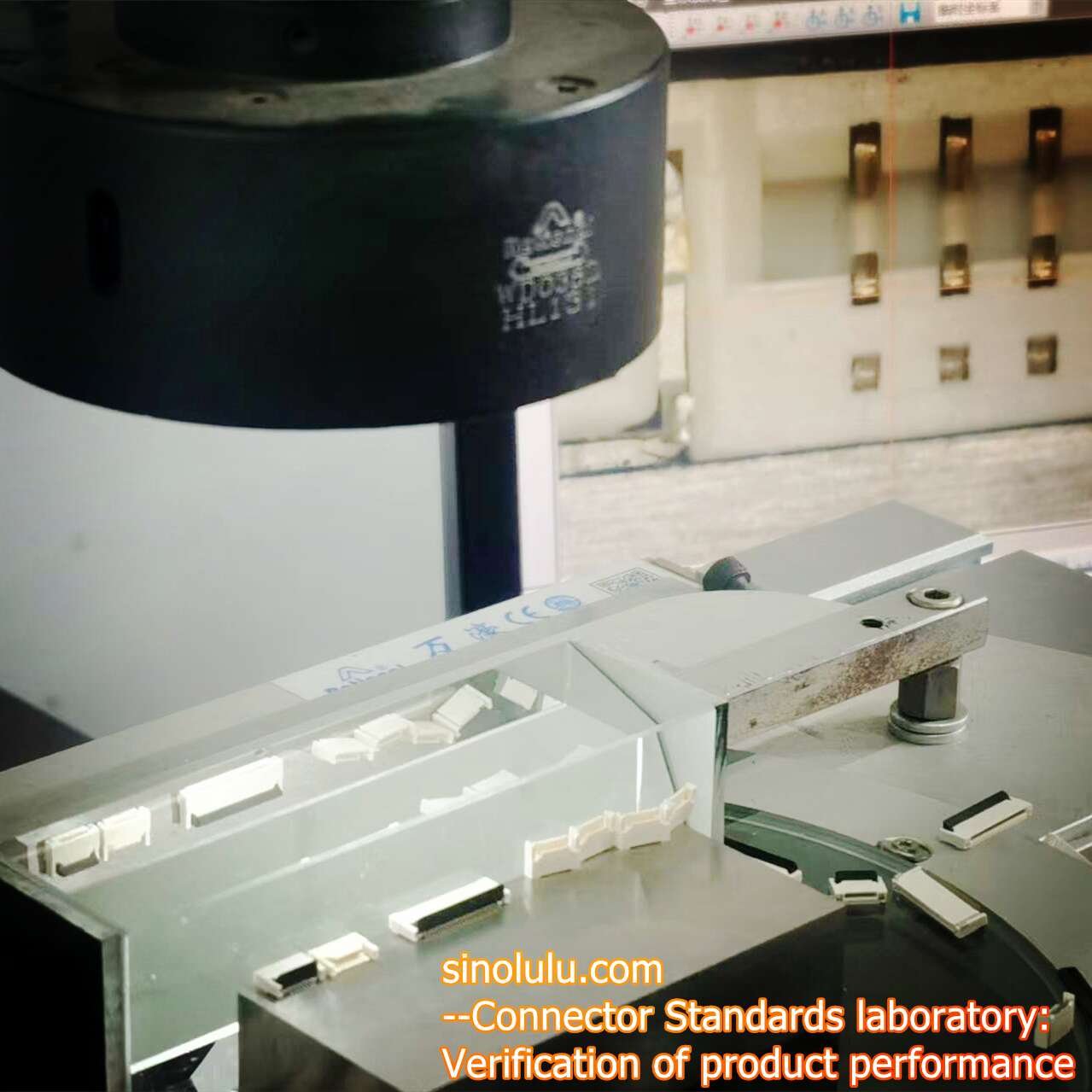

Standard Production Inspection Procedures (SOP)

Our Experienced engineers make sure each parts meet the more precision requirements

At Sinolulu, we pride ourselves on providing high-quality, customizable FPC connectors that meet the specific needs of our clients. Here are the key advantages of choosing our services for customization or OEM/ODM manufacturing:

Our comprehensive range of FPC connectors includes:

Pitch Range: 0.3mm, 0.5mm, 0.8mm, and 1.0mm.

Height Options: 1.0mm, 1.2mm, 1.5mm, 2.0mm, and 2.5mm.

Pin Count: From 4 to 80 pins, and up to 96 pins.

Connector Types: ZIF (Zero Insertion Force) and NON-ZIF types.

Contact Points: Top contact, bottom contact, and dual contact.

Mounting Styles: DIP and SMT (Surface-Mount Technology).

Our products can replace those from well-known brands like MOLEX, HIROSE, and OMRON, offering you high-quality alternatives.

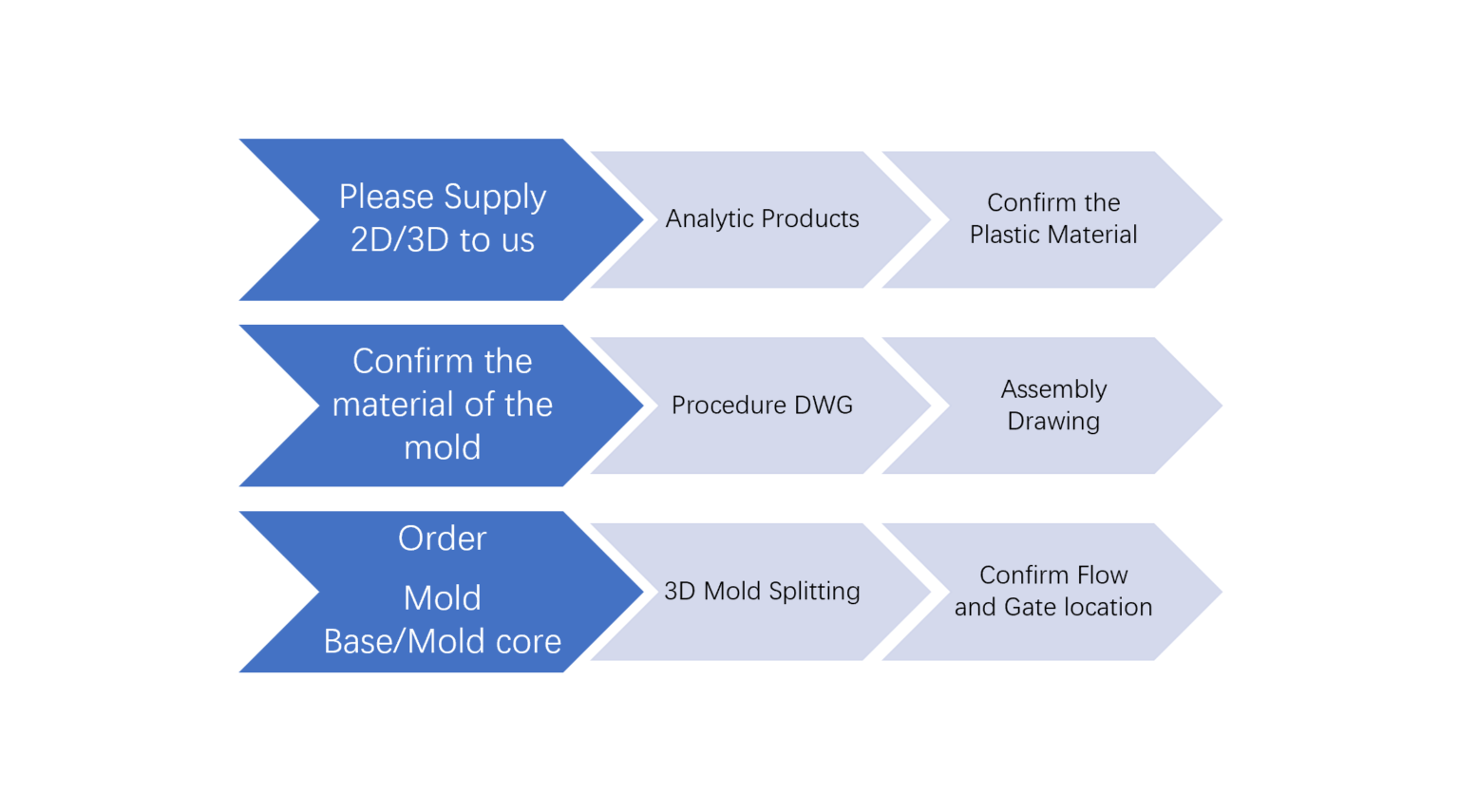

Initial Consultation and Sample Analysis:

Clients provide us with a physical sample or specific requirements.

Our expert R&D team performs a detailed analysis and dissection of the product.

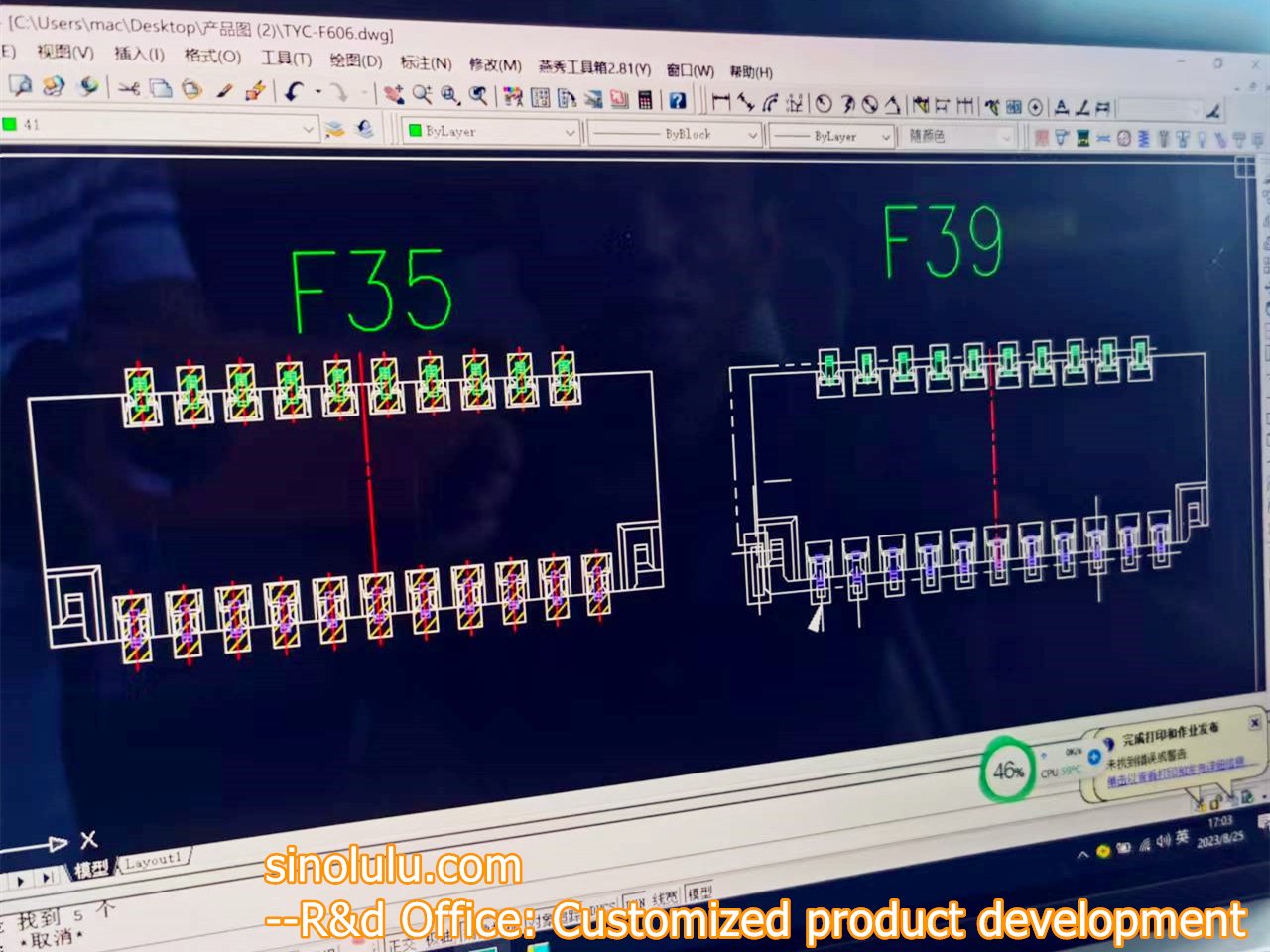

Design and Development:

We begin the design process, creating precise drawings and studying load balance.

High-quality steel is selected for mold manufacturing to ensure durability and accuracy.

Mold Manufacturing:

Our factory is equipped with a dedicated mold assembly room and spark machines for mold maintenance and parts supply, extending mold life and ensuring timely updates.

Injection Molding and Stamping:

We have 12 TOYO horizontal injection molding machines to guarantee precision and production capacity.

Six high-speed stamping machines for metal terminals.

A reputable electroplating facility located within 10KM of our factory ensures timely processing of terminals.

Assembly and Production:

For small quantities, we use manual assembly and packaging to ensure quality during initial SMT trial production.

For mass production, we develop specialized automatic assembly machines to enhance production efficiency and reduce labor costs.

Testing and Quality Assurance:

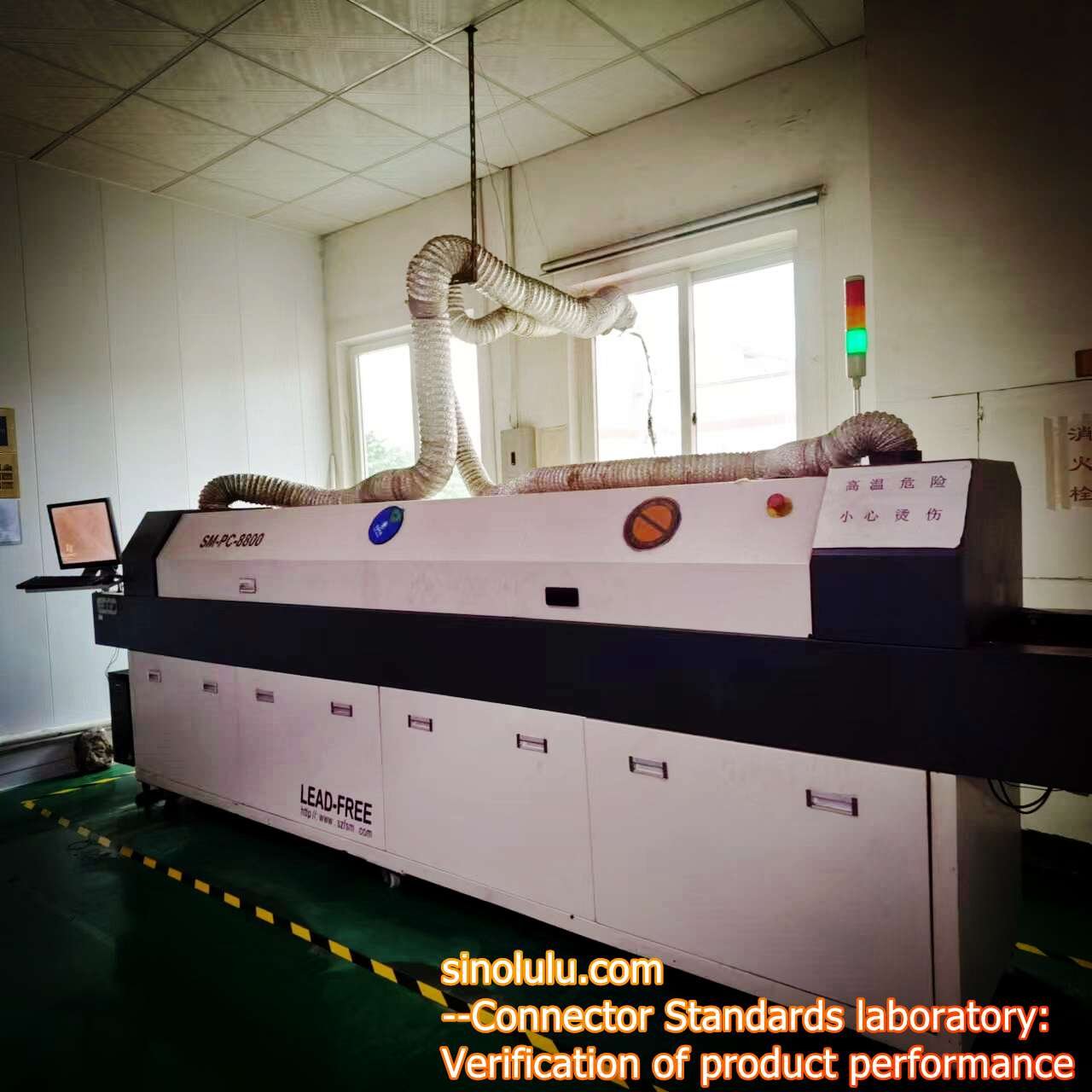

Post-development, our factory conducts simulated SMT tests to ensure connector performance.

We have a world-class standard testing laboratory equipped with temperature and humidity test chambers, IR reflow ovens, salt spray testers, microscopes, RoHS testers, ovens, pull force testers, solderability testers, and low impedance insulation testers.

Our stringent QA processes ensure top-notch product quality:

IQC: Incoming Quality Control.

IPQC: In-Process Quality Control.

FQC: Final Quality Control.

OQC: Outgoing Quality Control.

Our factory holds ISO9001 certification and has over 20 years of experience in connector manufacturing, making us fully capable of handling your OEM/ODM orders.

Professional After-Sales Team:

Our dedicated team provides comprehensive support to address any issues that may arise during SMT processing or assembly, ensuring minimal disruption and quick resolution.

Experience and Expertise:

With over two decades in the electronic connector industry, we have encountered and resolved numerous technical challenges, providing reliable support to our clients.

Commitment to Excellence:

By choosing Sinolulu, you are not only selecting a reliable product but also partnering with a professional team committed to your success.

For any inquiries or to discuss your specific requirements, please feel free to contact us. We are dedicated to providing the best solutions for your electronic connector needs.

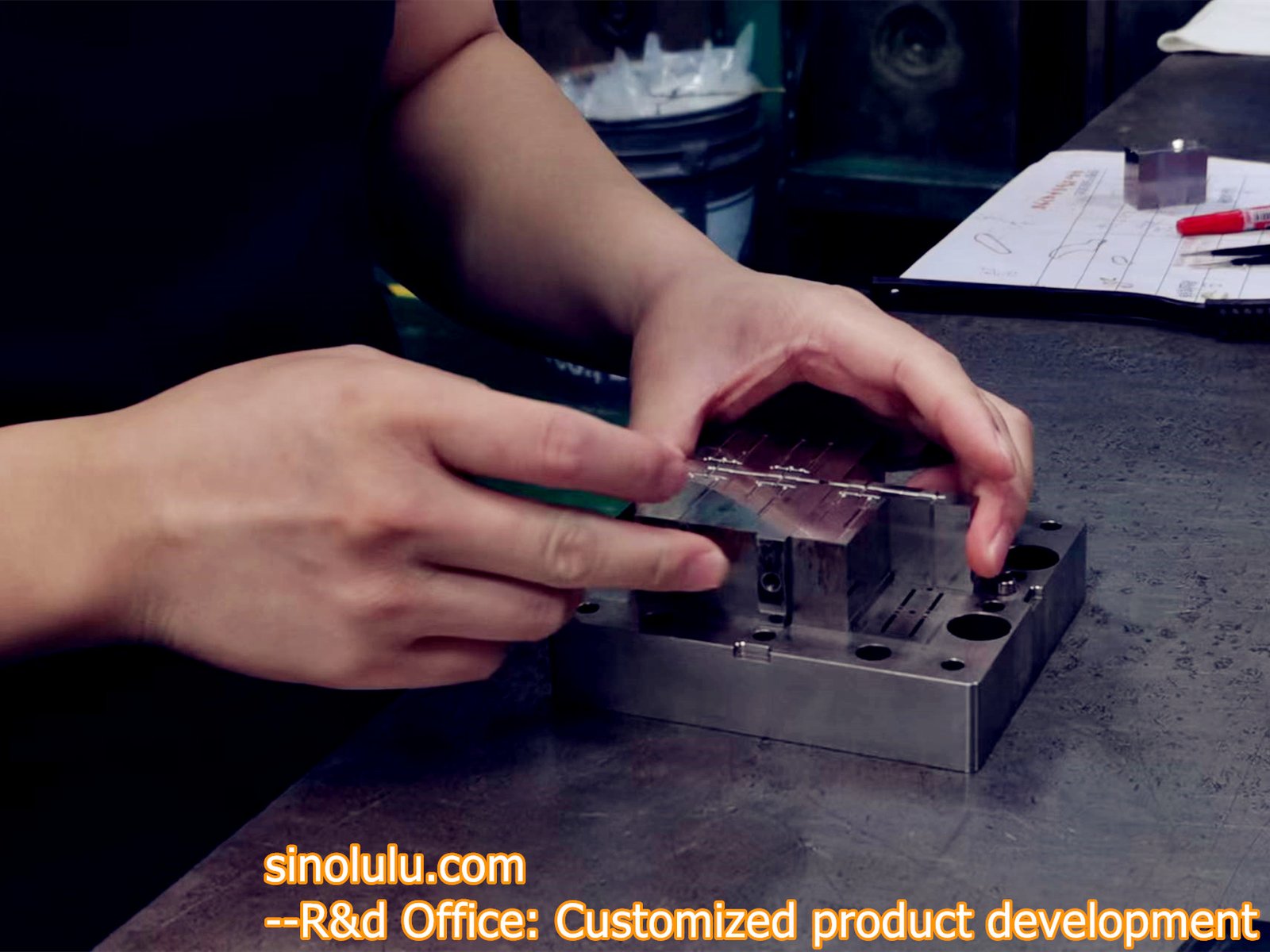

Customized Your own Products OEM/ODM Service Customized your Parts @sinolulu

R&D department: customized products

For newly developed products, we have a standard connector laboratory to verify the performance of new products

Send your Drawing, We will evaluated price for you Soon!

Certificates

Suitable for high strictly quality

Currently our factory and products have the qualification

1. ISO 9001

2. Chinese hi-tech firms

3. We have 18 patents a year on our products

4. Our products have SGS certification

Fairs

Since 2010, we have participated in exhibitions in Hong Kong, India and Thailand, Shanghai.

Frequently Asked Question

Here you can quickly find answers to some common questions. If the answer you’re looking for isn’t listed, please contact us directly.

About Lulu and Sinolulu.com

Welcome to Sinolulu.com! I’m Lulu, and I have dedicated the past 14 years to the electronic connector industry, specializing in the production, sales, and after-sales service of connectors. My extensive experience and in-depth knowledge allow me to provide exceptional support and solutions for all your connector needs, particularly FPC (Flexible Printed Circuit) connectors.

Professional Expertise

Over the years, I have honed my skills and expertise in several key areas:

Production:

- Understanding the intricacies of connector manufacturing processes.

- Ensuring high-quality production standards for reliable and durable connectors.

Sales:

- Providing detailed product information to help clients make informed decisions.

- Tailoring sales strategies to meet the unique needs of domestic and international markets.

After-Sales Service:

- Offering comprehensive support to ensure the optimal use and longevity of connectors.

- Addressing any issues promptly to maintain customer satisfaction.

Your Trusted Sales Engineer

As a professional sales engineer, my goal is to solve any issues you may encounter with electronic connectors. Whether you are looking for a specific type of connector or need assistance with pre-sales selection, purchasing, or post-purchase usage, I am here to help. My extensive knowledge allows me to quickly identify and provide the best solutions for your requirements.

Expertise with Global Clients

I have had the privilege of working with some of the world’s leading companies, including Foxconn, Huawei, Xiaomi, Qisda, and Amazon’s EMS. This experience has given me valuable insights into the needs and expectations of top-tier clients, enabling me to deliver solutions that meet the highest standards of quality and reliability.

Comprehensive Connector Solutions

At Sinolulu.com, you will find a wide range of connectors, including specialized FPC connectors. My services include:

- Pre-Sales Selection: Helping you choose the right connector for your specific application.

- Purchasing Guidance: Providing all the information you need to make a confident purchase.

- Post-Purchase Support: Ensuring you get the most out of your connectors with expert advice and troubleshooting.

Familiarity with Sales Processes

I am well-versed in both domestic and international sales processes, ensuring smooth transactions and efficient communication with clients from around the world. My experience in handling complex sales operations allows me to manage your orders with precision and care.

Contact Me

If you have any questions or need assistance, please feel free to contact me. I am committed to providing you with the best possible service and helping you find the perfect connectors for your needs.

Thank you for visiting Sinolulu.com. I look forward to working with you and providing the solutions you need to succeed.

Best regards,

Lulu

Sinolulu.com

About Sinolulu’s Factory

Welcome to Sinolulu, where we combine years of expertise with cutting-edge technology to deliver top-quality electronic connectors. Our factory, located in Shenzhen, China, has a rich history and robust capabilities to meet the global demands of electronic component manufacturing.

Our Journey

1994 – Establishment in Taoyuan, Taiwan: Sinolulu began its journey in Taoyuan, Taiwan, focusing on developing plastic molds for electronic components. Our early years were dedicated to mastering the art of precision mold-making, which laid a strong foundation for our future growth.

2004 – Expansion to Shenzhen, China: With the rapid economic development, we expanded our operations to Shenzhen, China. This move marked a significant shift in our capabilities. We transitioned from solely developing plastic molds to incorporating injection molding and metal stamping into our processes. This expansion allowed us to start assembling finished PCB board-end electronic connectors, primarily producing wire-to-board connectors used in computers.

2006 – Entering the FPC/FFC Connector Market: As electronic products evolved, so did our product offerings. In 2006, we began developing and producing FPC (Flexible Printed Circuit) and FFC (Flexible Flat Cable) connectors, focusing on pitches of 0.5mm and 1.0mm. This development was in response to the growing demand for more compact and efficient connectors in modern electronic devices.

2009 – Launching the 0.3mm Pitch FPC Connector: Our innovation continued with the introduction of the 0.3mm pitch FPC connector in 2009. This milestone marked our official entry into the FPC connector business, including ZIF (Zero Insertion Force) and NON-ZIF connectors. This product expansion has allowed us to meet the increasing complexity and miniaturization demands of the electronics industry.

Our Capabilities

Today, Sinolulu’s factory is equipped with state-of-the-art facilities and advanced machinery, enabling us to handle global orders for electronic components efficiently:

- R&D Office: Our dedicated research and development office focuses on creating new and innovative electronic connectors to meet the ever-evolving market needs.

- Mold Processing Workshop: Equipped with high-precision tools, our workshop can produce intricate molds required for various electronic components.

- Mold Assembly Room: Our skilled technicians assemble the molds with utmost precision, ensuring high-quality outputs.

- TOYO Injection Molding Machines: We have 12 advanced TOYO injection molding machines that ensure consistent and high-quality production.

- Automatic Assembly Machines: With 60 automatic assembly machines, we can produce connectors at scale while maintaining high standards.

- Global Standard Connector Laboratory: Our laboratory is equipped to perform rigorous testing, ensuring our connectors meet international quality and reliability standards.

Certifications

- ISO9001 Certified: Our factory is ISO9001 certified, ensuring we adhere to the highest standards of quality management.

- SGS Certified Products: Our products have SGS certification, which guarantees that they meet stringent safety and environmental criteria.

Our Clients

We are proud to serve some of the world’s leading companies, including:

- Foxconn

- Amazon

- Qisda

- Xiaomi

- Huawei

Our clients trust us for our commitment to quality, innovation, and reliability. We continually strive to exceed their expectations by delivering products that meet the highest standards of excellence.

Contact Us

If you have any questions or need assistance, please feel free to contact us. We are committed to providing you with the best possible service and helping you find the perfect connectors for your needs.

Thank you for considering Sinolulu as your trusted partner in electronic connectors. We look forward to working with you and providing the solutions you need to succeed.

Best regards,

Lulu

Sinolulu.com

Welcome to Sinolulu

FPC (Flexible Printed Circuit) connectors are essential electronic components that you won’t typically see in your daily life, but they play a crucial role inside the electronic devices you use every day. If you’ve found your way to our website, Sinolulu, you might be:

- Searching for an FPC Connector: Perhaps you’re looking to purchase an FPC connector for your project or business.

- An Engineer Designing a New Product: You might be in the process of designing a new product and need the right connectors to ensure its functionality and reliability.

- Seeking Help with a Problem: Maybe you’re experiencing issues with a product you’ve previously used and need expert advice or replacement parts.

No matter what brings you here, I’m here to help you. With 14 years of experience in the electronic connector industry, I can assist you with:

- Finding the Right Connector: Helping you select the perfect FPC connector for your specific needs.

- Design Consultation: Providing guidance and recommendations during the design phase of your product.

- Troubleshooting and Support: Offering expert advice to solve any issues you might be facing with your connectors.

Please feel free to reach out to me via email for any inquiries or support. I’m committed to providing the best solutions to meet your needs.

Thank you for visiting Sinolulu. Let’s make your project a success together!

Best regards,

Applications of FPC Connectors

FPC (Flexible Printed Circuit) connectors are versatile and used in a wide range of applications due to their flexibility, compact size, and reliability. Here are some primary applications:

Consumer Electronics:

- Smartphones and Tablets: Connecting displays, cameras, and sensors to the mainboard.

- Wearable Devices: Used in smartwatches and fitness trackers for connecting displays, batteries, and sensors.

Automotive Electronics:

- Dashboard Displays and Infotainment Systems: Connecting various displays and control units within vehicles.

- Rearview Cameras and Sensors: Ensuring reliable connections in automotive safety systems.

Medical Devices:

- Portable Medical Monitors: Connecting displays and control modules in devices like glucose monitors and portable ECG machines.

- Imaging Equipment: Used in ultrasound and other diagnostic equipment for connecting sensors and displays.

Industrial Control and Automation:

- Human-Machine Interfaces (HMIs): Connecting touchscreens and control units in industrial control panels.

- Robotics: Used in robotic arms and automated systems to connect sensors and actuators.

Home Appliances:

- Smart Home Devices: Connecting various modules in smart locks, thermostats, and other home automation products.

- Kitchen Appliances: Used in modern appliances with touchscreens and advanced control systems.

Gaming and Virtual Reality:

- Game Consoles: Connecting components within gaming devices.

- VR Headsets: Ensuring flexible and reliable connections for displays and sensors.

Contact Us

If you have any questions or need assistance, please feel free to contact us. We are committed to providing you with the best possible service and helping you find the perfect connectors for your needs.

Thank you for considering Sinolulu as your trusted partner in electronic connectors. We look forward to working with you and providing the solutions you need to succeed.

Best regards,

Yes, we provide samples for testing and evaluation. Please contact us to request samples.

Yes, we provide samples for testing and evaluation. Please contact us to request samples.

The lead time for orders varies based on the order quantity and customization requirements. Standard products typically ship within 2-4 weeks.

Yes, detailed technical documentation, including datasheets and user manuals, is available for all our products.

Some projects we have to keep secret. But most of our connectors are used in display modules, camera modules, and touch modules, and so on.

Yes, we offer customization services to meet specific requirements, including changes in size, shape, pin count, and materials.

Yes, our connectors comply with industry standards such as UL, RoHS, and REACH. Certification documentation is available upon request.

Our connectors are constructed using high-quality materials. The housing is typically made from heat-resistant plastic, while the pins are made from phosphor bronze or beryllium copper with gold or tin plating for enhanced conductivity and corrosion resistance.

Yes, we provide comprehensive technical support and after-sales services to ensure customer satisfaction.

Our connectors come with a standard one-year warranty covering manufacturing defects.(Golden) Extended warranty options are available upon request.(6 months for Tin)

30+Years Factory

From1994, to the processing and assembly of injection parts

Famous Customer

Our customers are from the world's top EMS factories

24*7 Service

10+ years of experience of sales engineers one-on-one service

Accept OEM/ODM

Accept custom plastic and hardware accessories