Requirements for Creating High-Quality, Durable Precision Plastic Molds

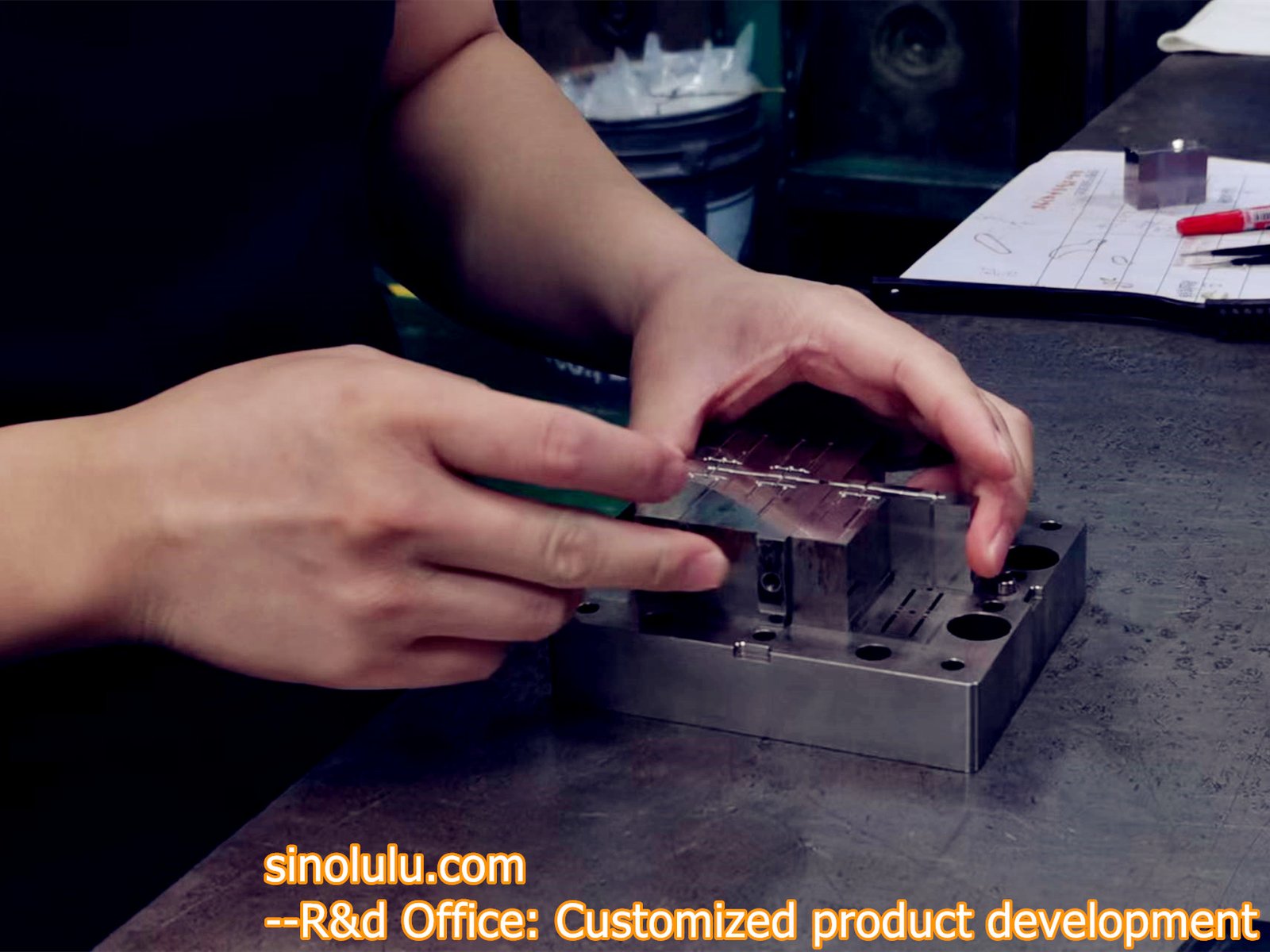

Our FPC connectors have a pitch of 0.3mm, which demands high precision in mold making. Since 1994, we have been specializing in precision plastic molds. To achieve the necessary precision and durability, what aspects must a qualified and durable precision plastic mold address?

Our FPC connectors feature a 0.3mm pitch, requiring extremely high precision in mold manufacturing. Since 1994, we have been specializing in producing precision plastic molds. To ensure that a mold is both precise and durable, it must meet several key criteria:

- Material Selection:

- Use high-grade tool steel, such as P20, H13, or stainless steel, for mold bases and cavities.

- Apply surface treatments like nitriding or PVD coatings for enhanced wear resistance.

- Design Precision:

- Utilize advanced CAD/CAM software for accurate mold design.

- Maintain tight tolerances during the design phase.

- Machining Accuracy:

- Employ high-precision CNC machines for mold fabrication.

- Use EDM for creating complex geometries and fine details in the mold cavities.

- Quality Control:

- Perform dimensional inspections using tools like CMM.

- Ensure smooth and defect-free mold surfaces.

- Cooling System Design:

- Design efficient cooling channels to maintain uniform mold temperatures.

- Conduct thermal analysis to optimize the cooling system.

- Mold Assembly and Testing:

- Assemble mold components with high precision.

- Conduct trial runs and make necessary adjustments.

- Maintenance and Longevity:

- Implement a regular maintenance schedule.

- Properly lubricate and handle molds to extend their lifespan.

- Documentation and Process Control:

- Maintain detailed records of mold design and machining parameters.

- Implement strict process control measures during molding operations.

By adhering to these principles, you can ensure that your molds produce high-quality parts consistently and have a long operational life.