Products & Service

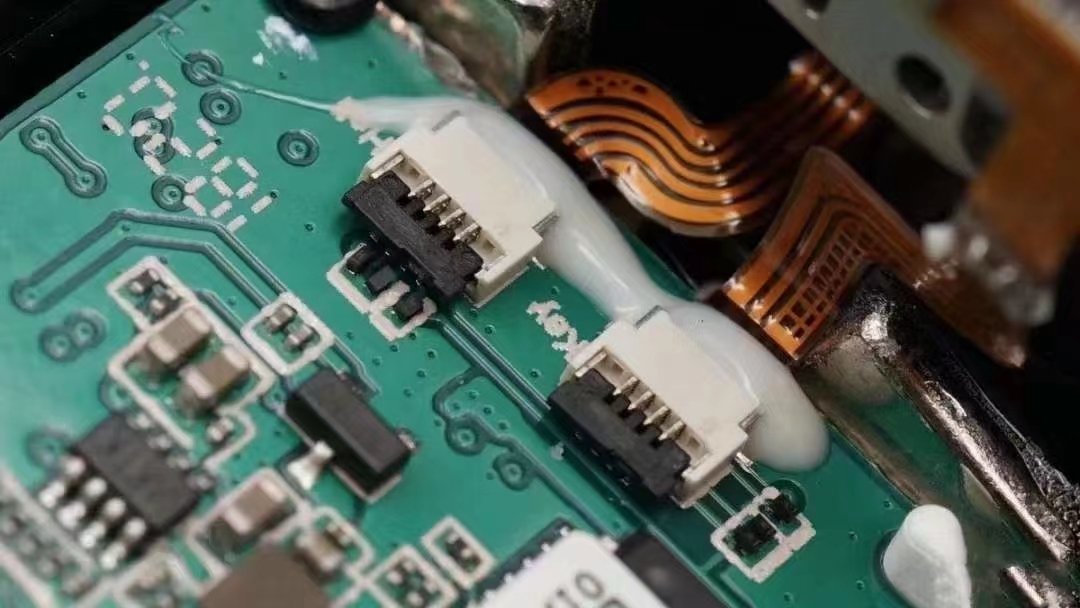

Existing Connector

FPC/FFC Connector/Wire to Board Connector/Board to Board Connector

Alternative/replace Molex, Hirose, and Omron Connector: FH26, FH19, FH35C, FH34, XF2M, XF3M…

OEM/ODM Service

OEM: We have equipment to process your connectors.

ODM: We have 30+ years of connector experience and can customize the connector according to your actual use environment

Existing Connector

Products

Exisiting Connectors

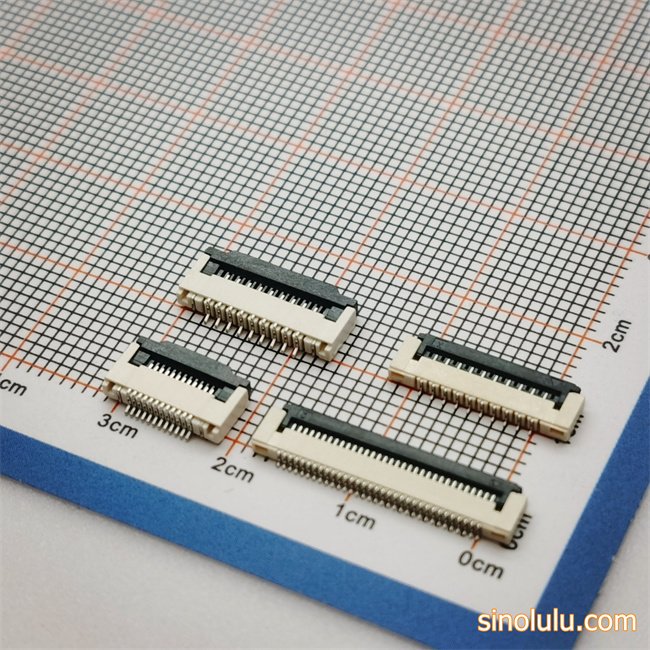

According to the feedback of the market, we have made many connectors that can replace the original factory, such as: Hirose, molex, Omron, JST… with good quanlity and short L/T.

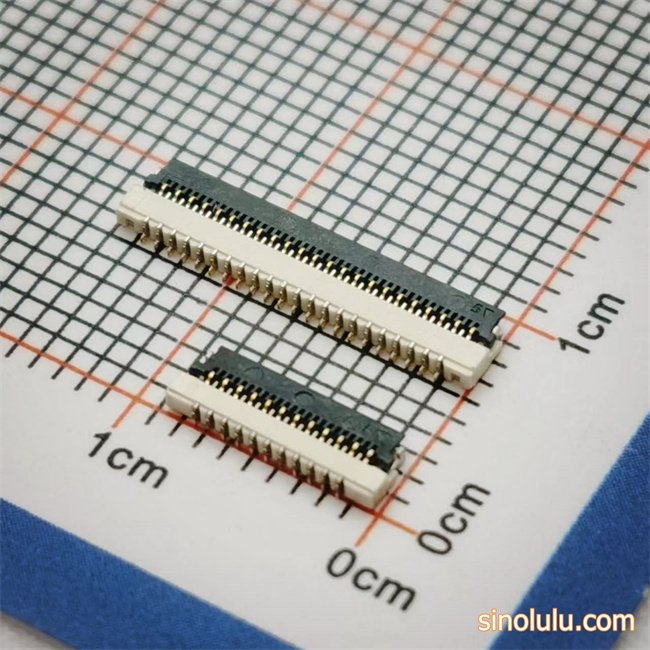

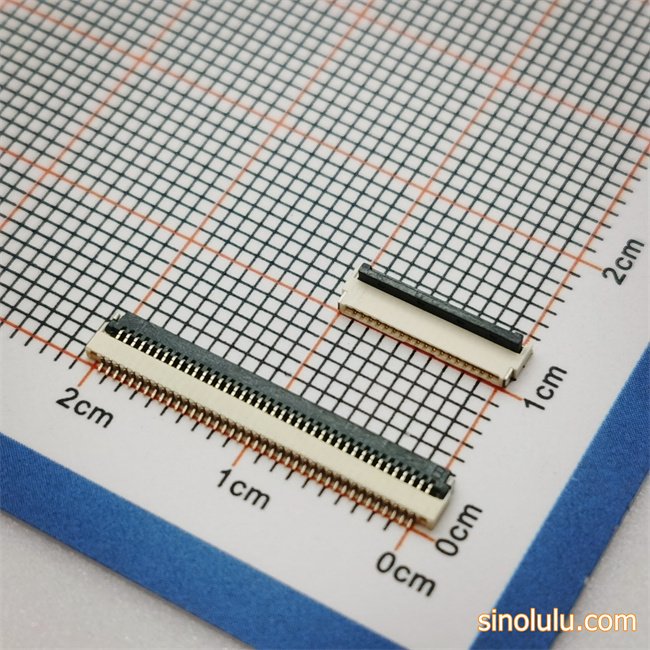

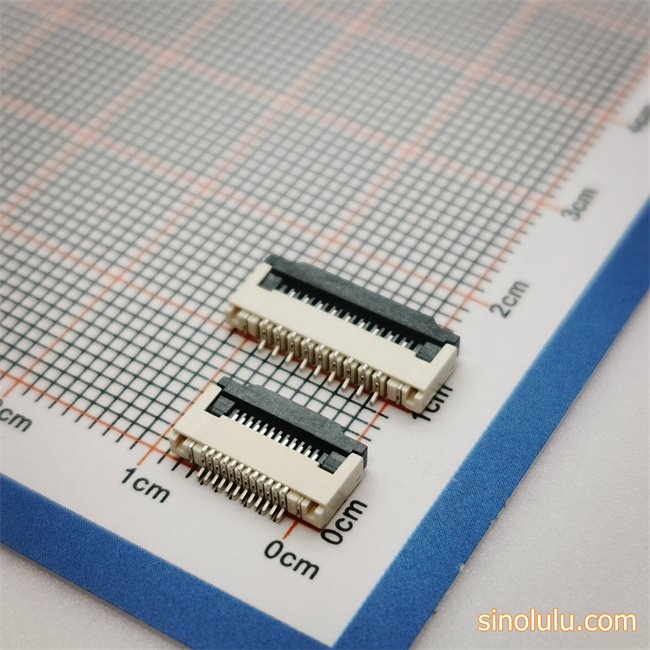

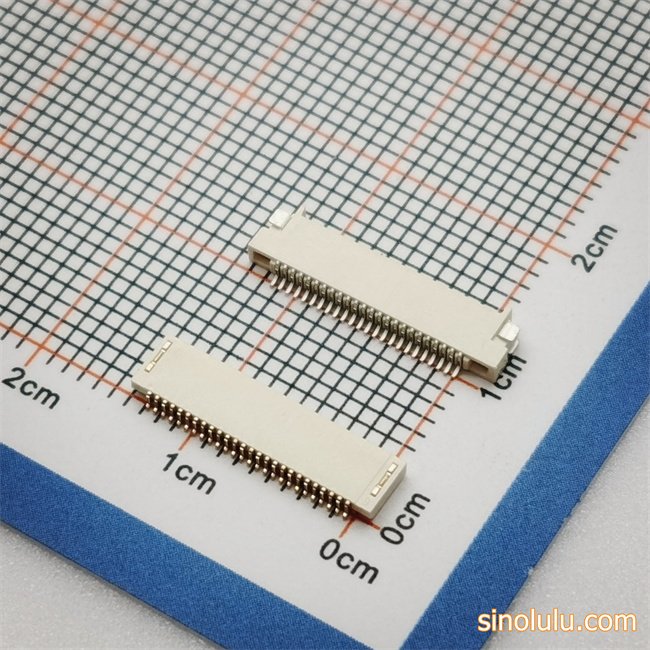

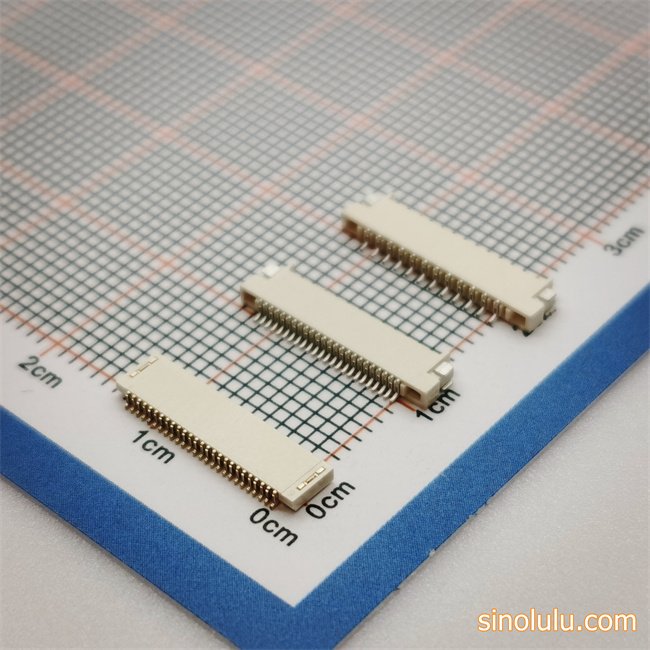

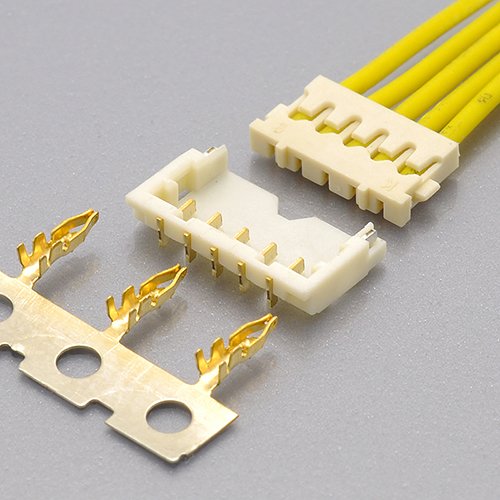

FPC Connector

ZIF/NON-ZIF; PITCH:0.3mm/0.5mm/1.0mm; Flip-Lock/Back Lock; SMT/DIP

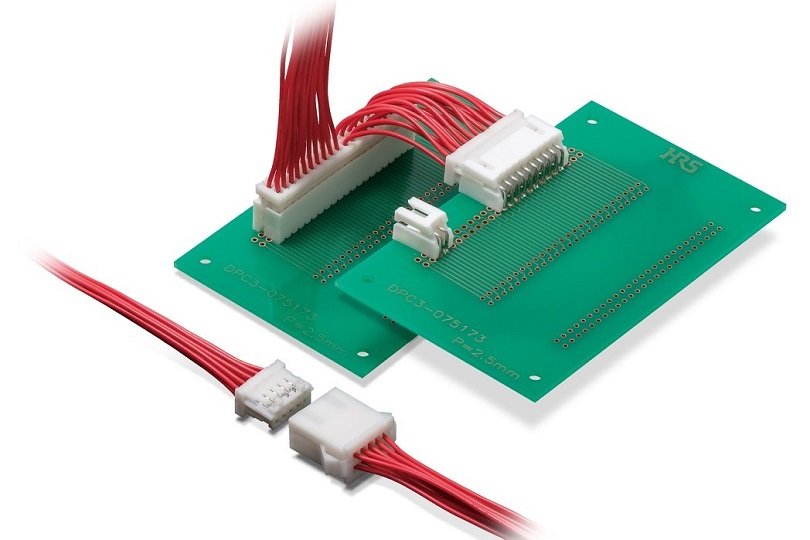

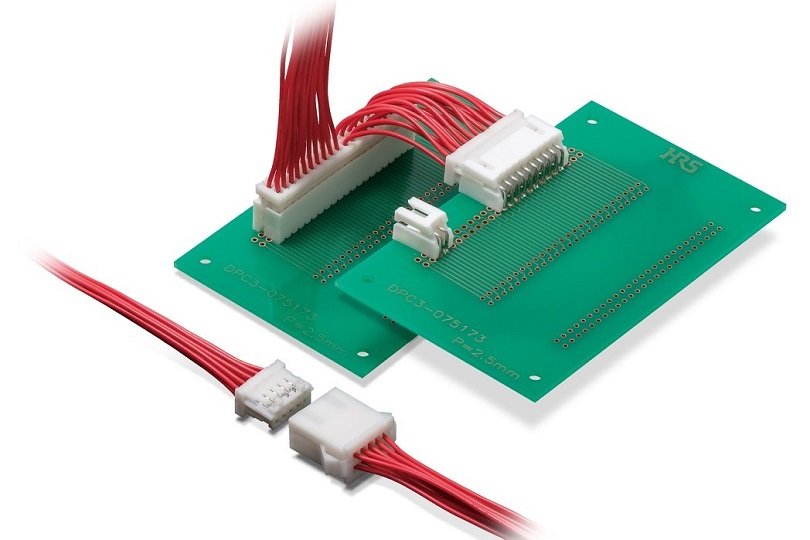

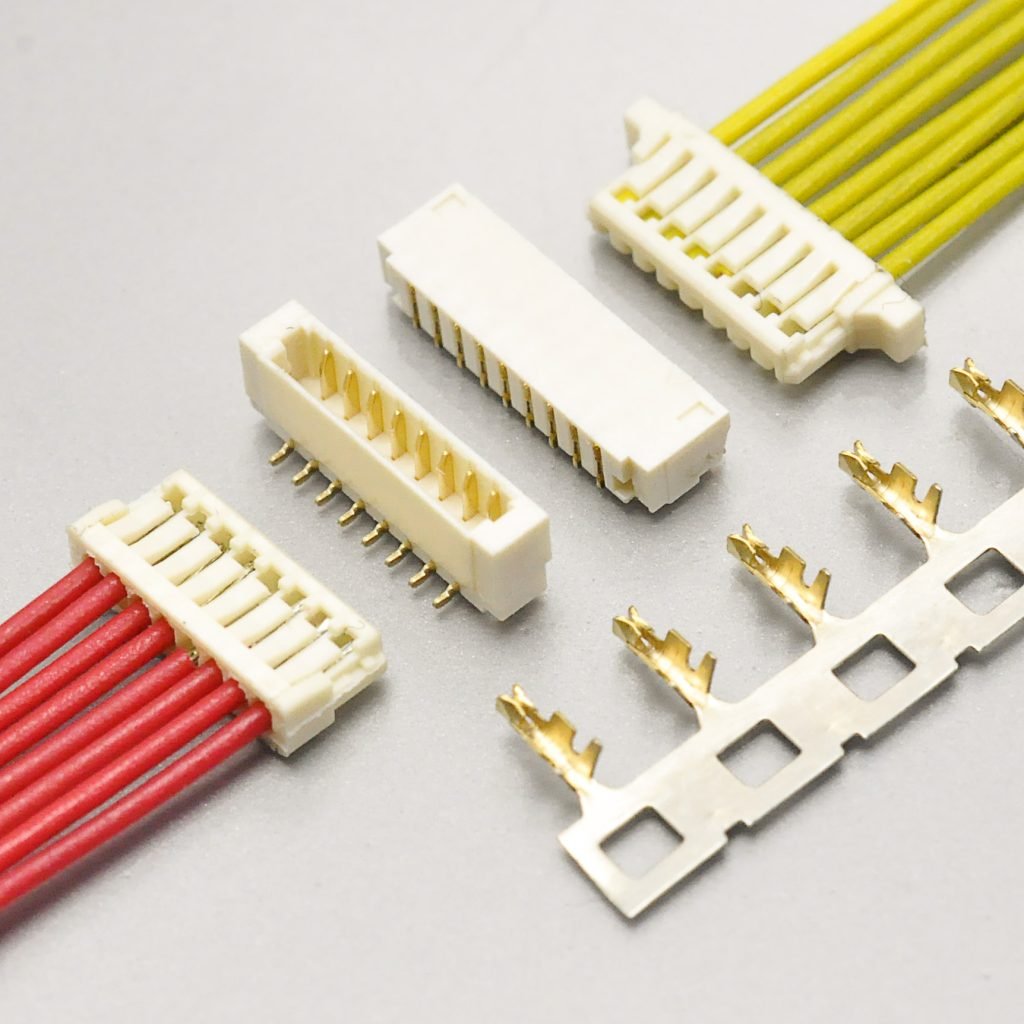

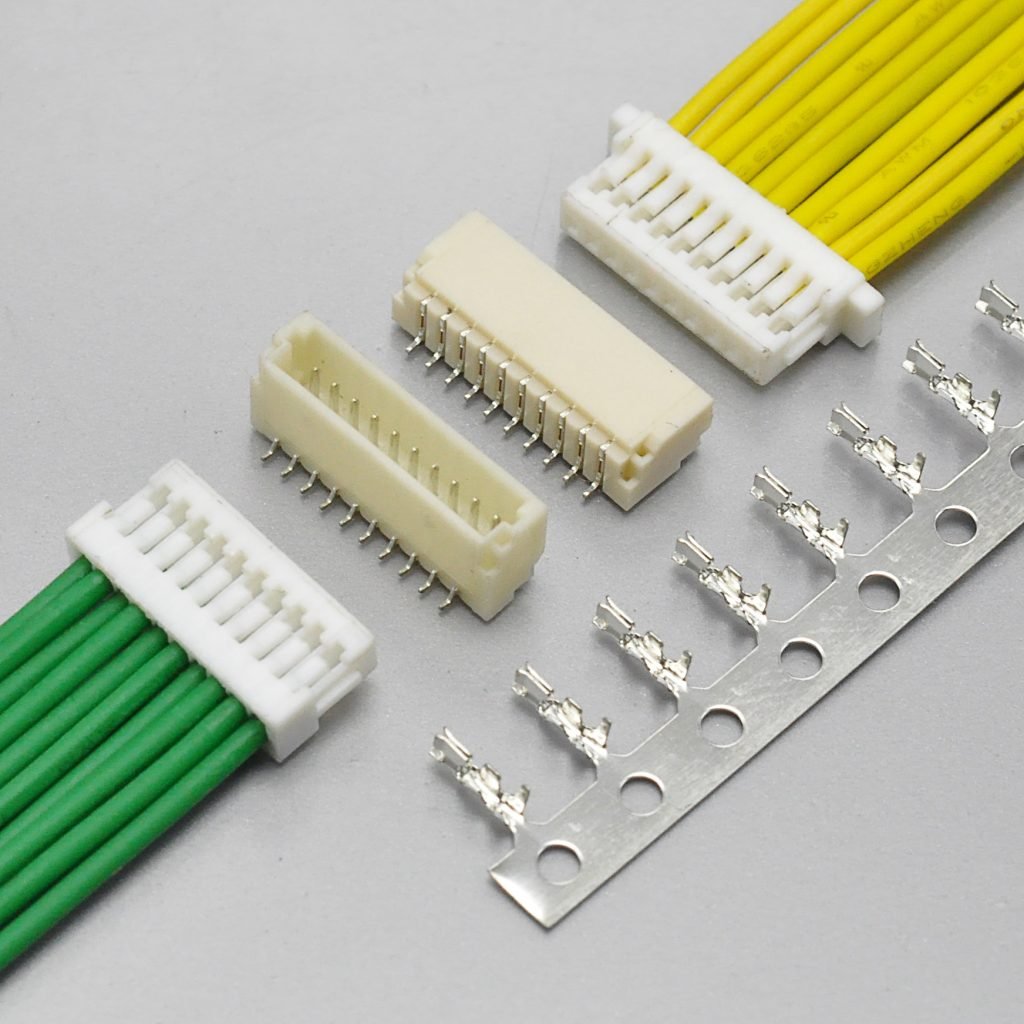

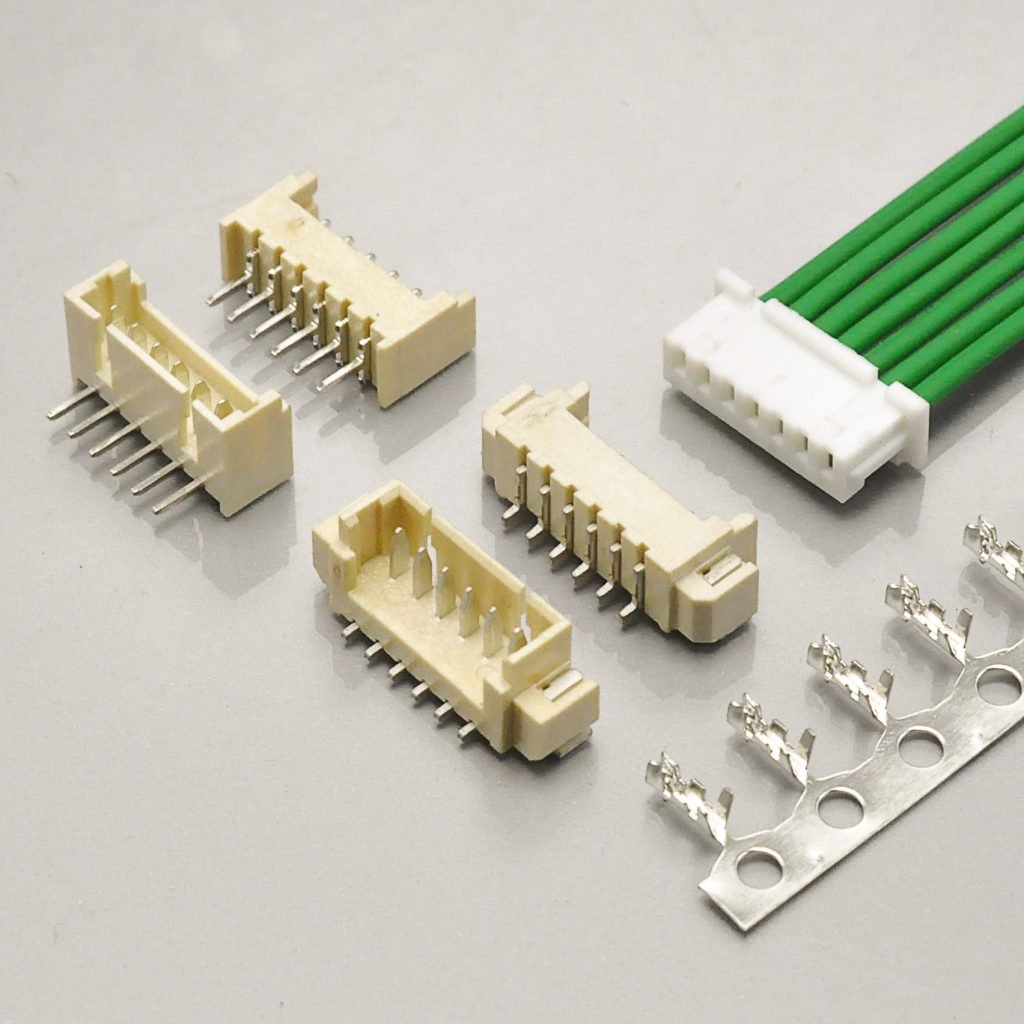

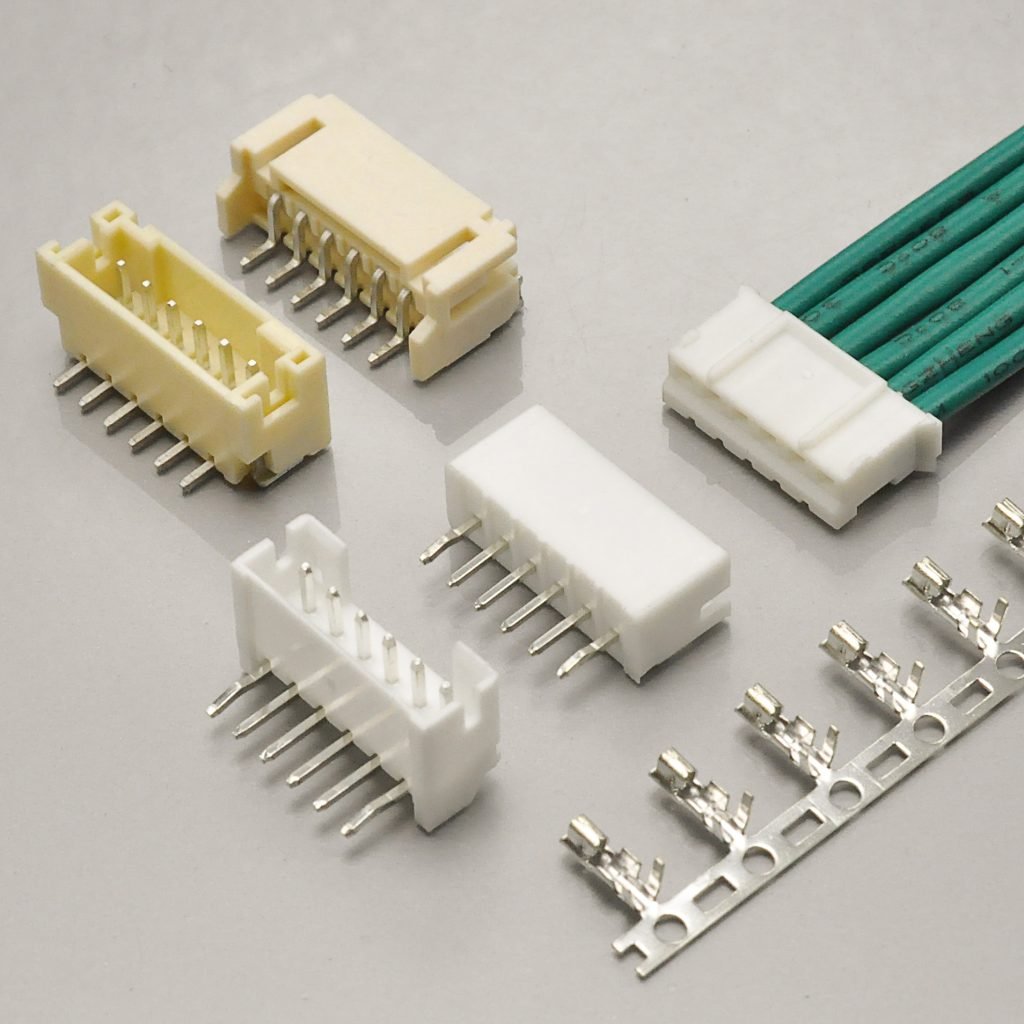

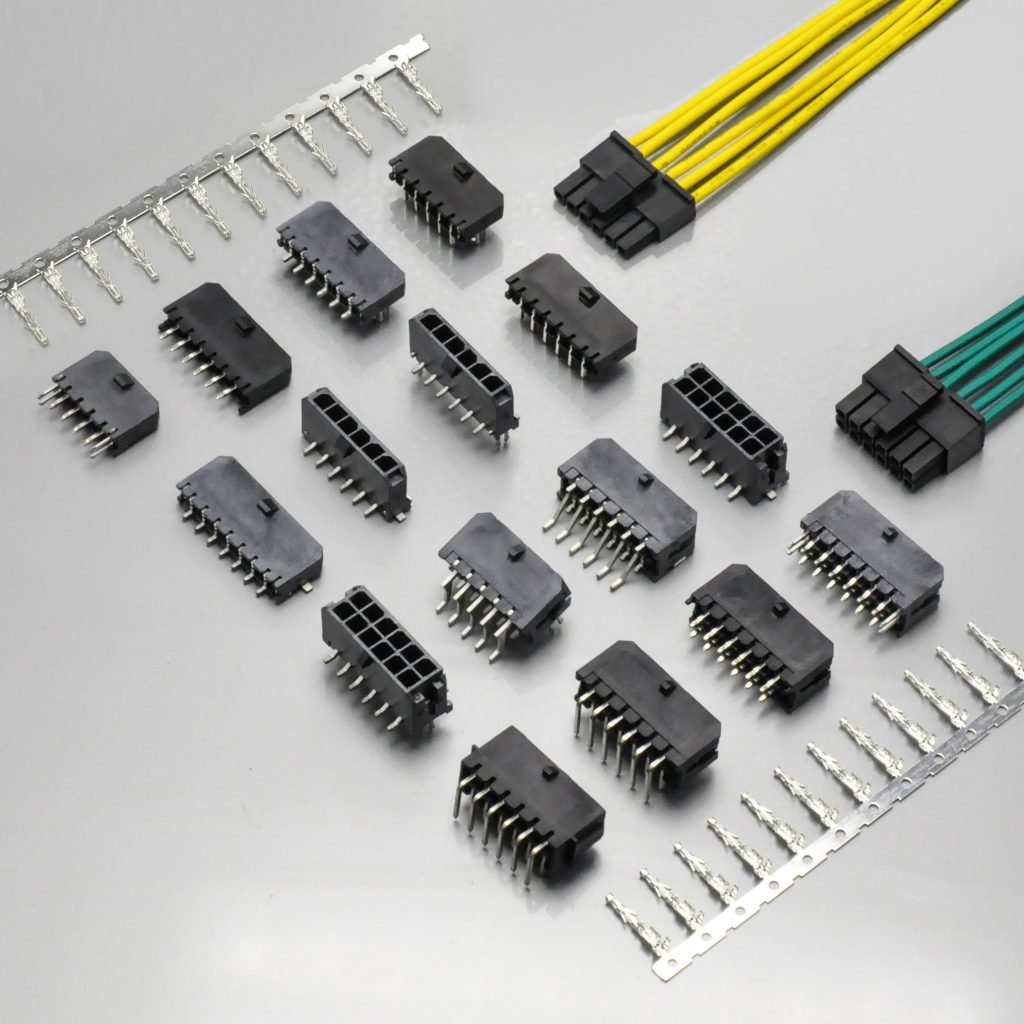

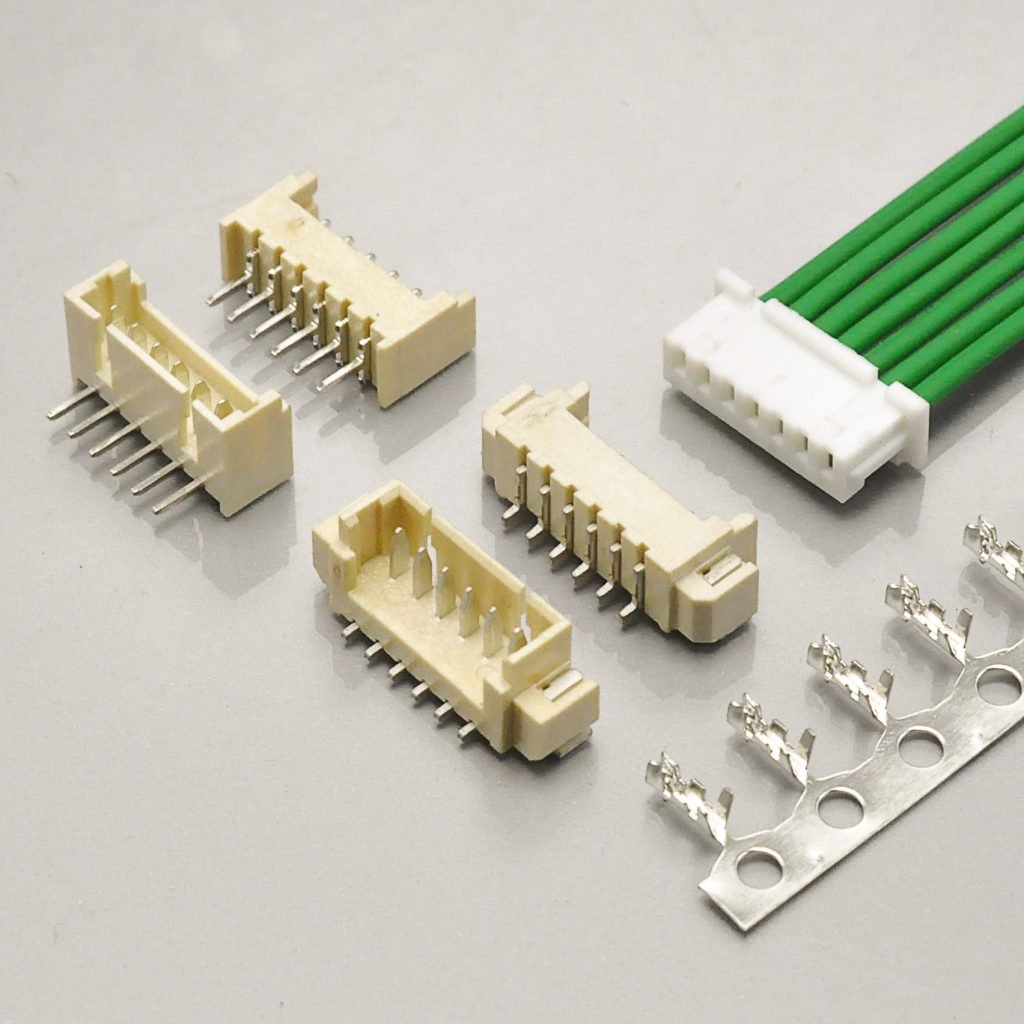

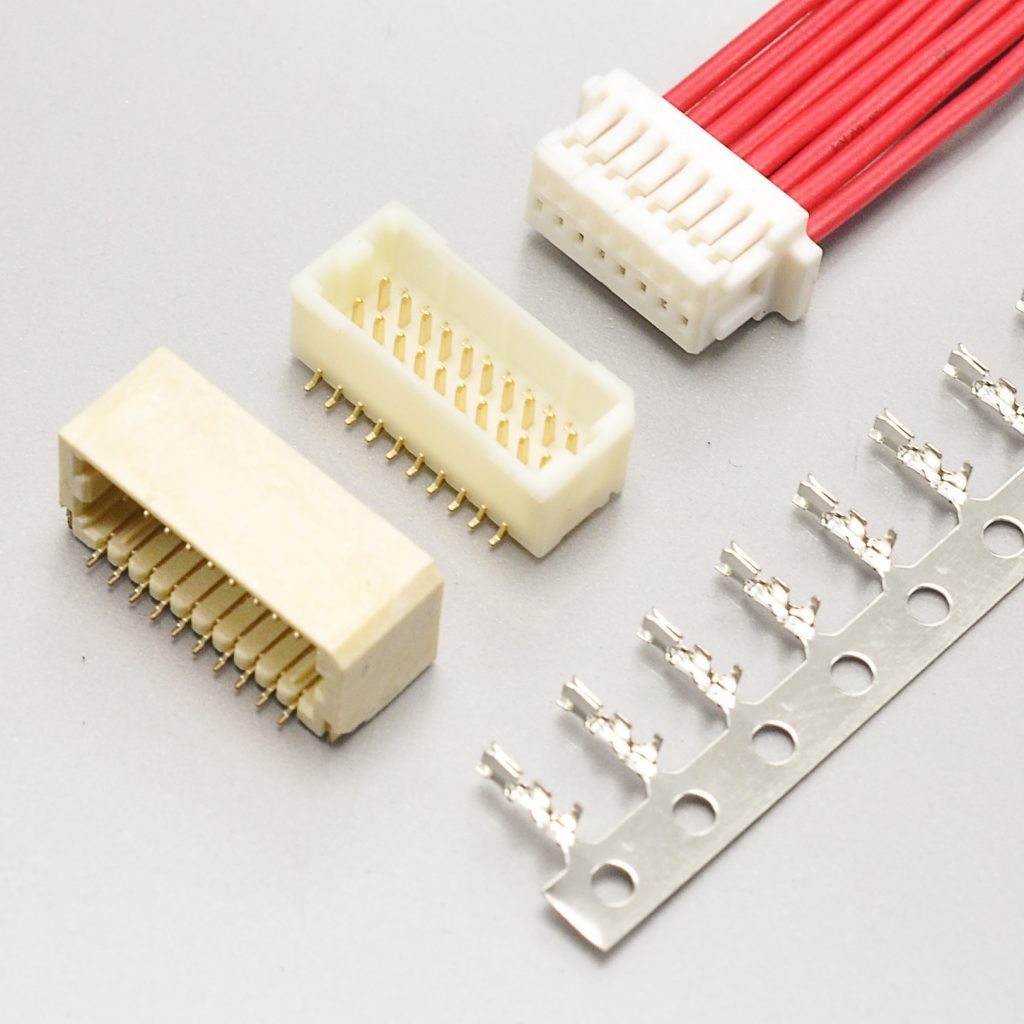

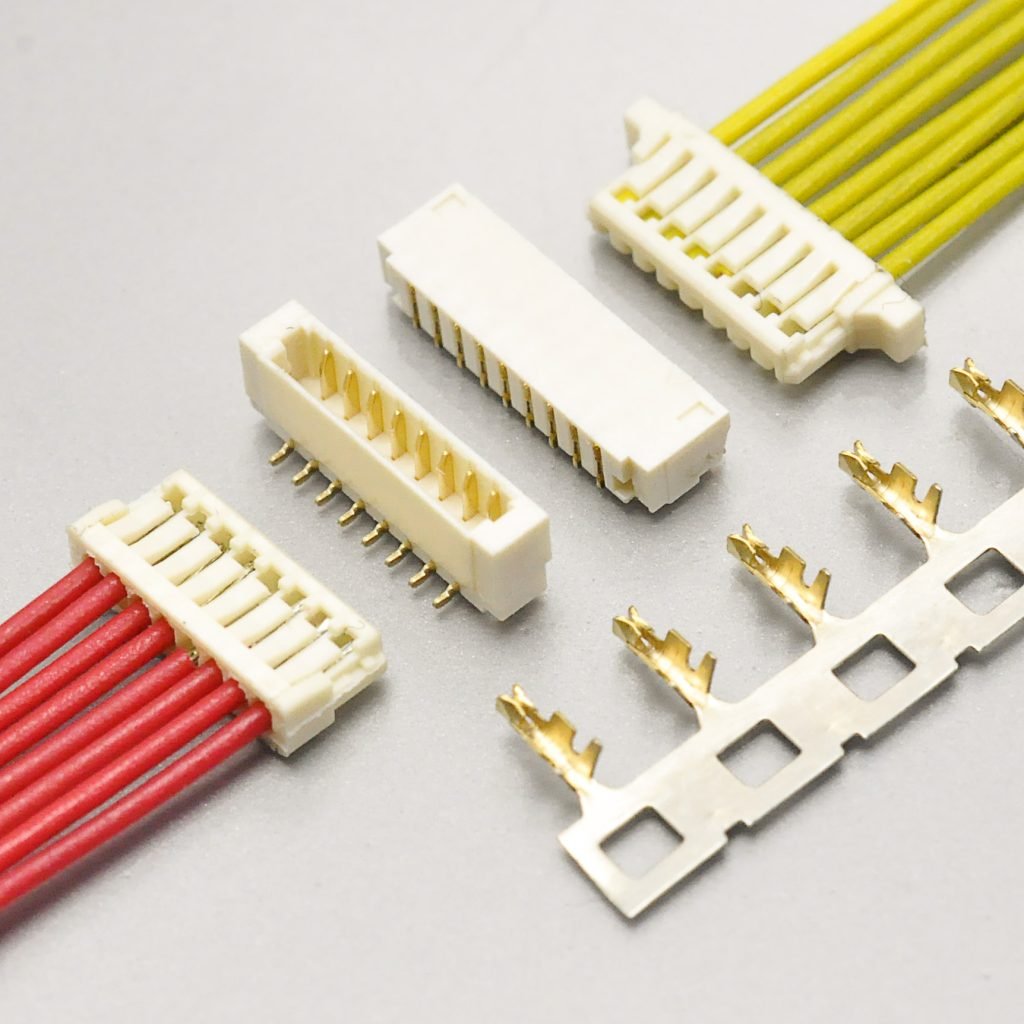

Wire to Board Connector

Pitch: IDC0.6mm/0.8mm/ 1.0mm/1.25mm/2.0mm/2.5mm/3.0mm

Board to Board Connector

Can replace Hirose, Panasonic, molex.

FPC Connector

According to the Pitch of Connectors, there are 0.3mm, 0.5mm, 0.8mm, 1.0mm

According to the Insertion force of FPC/FFC Cable, there are NON-ZIF and ZIF

FPC0.3MM

P/N: EW31-XXRL-TAG EW394-XXRL-TAG

FPC0.5MM

P/N: EW51-XXRL-TAG EW509-XXRL-TAG

FPC0.8MM

P/N: EW826/827

FPC1.0MM

P/N: EW123

NON-ZIF

P/N: EW121/123/511

ZIF

P/N: EW529

FPC Connector Catelogue

No. | Pitch (mm) | Height?(mm) | Spefication | Part No. | Pin Range | Packaging | MOQ |

1 | 0.3 | 1 | Bottom Contact, Front Flip | EW31 FPC0310 | 13-73P | Reel | 5000pcs |

2 | 0.3 | 1 | Back Flip, Top and Bottom Contact | EW394 FPC0394 | 11-51P | Reel | 3500PCS |

3 | 0.5/1.0 | 1 | Lower Contact, Front Flip | EW51 FPC0510 | 4-50P | Reel | 5000pcs |

4 | 0.5/1.0 | 1 | Back Flip, Top and Bottom Contact | EW509 FPC0509 | 4-50P | Reel | 3500pcs/4000pcs |

5 | 0.5 | 1.2 | ?Easy-On? Right-Angle, Non-ZIF, Dual Contact Style,? Gold (Au) Plating | EW511 FPC0511 MX51281XX | 4-50P | Reel | 3000pcs |

6 | 0.5/1.0 | 1.2 | Right-Angle, Surface Mount, ZIF, Top/Bottom Contact Style | MX54548/MX545500472 EW516/EW517 | 4-60P | Reel | 3000pcs |

7 | 0.5/1.0 | 1.5 | Right-Angle, Non-ZIF, Dual Contact Style,? | EW121/EW121/BL121/BL122/EW123/BL123 | 4-60P | Reel | 2500pcs |

8 | 0.5/1.0 | 1.5/2.0 | Bottom Contact, Front Flip | EW512-FPC0515/FPC0512/FPC0521/EW521 | 4-80P | Reel | 2000pcs |

9 | 0.5/1.0 | 2 | Slider Series, Right-Angle, Top/Bottom Contact | EW526/EW527 /52435 | 4-60P | Reel | 2000pcs |

10 | 0.5/1.0 | 2 | ?Dual sided Contact | EW529/EW1029/EW601/EW604 /XF2M/XF3M | 4-60P | Reel | 1500pcs |

Rotary Backlock |

| ||||||

11 | 0.5/1.0 | Vertical | Slider Series, Vertical | EW536/537 | 4-60P | Reel | 1000pcs |

12 | 0.8 | 2 | Slider Series, Right-Angle, Top/Bottom Contact | EW826/827 | 4-34P | Reel | 2000pcs |

13 | 1 | Vertical | Slider Series, Vertical | EW1038/EW1036/FPC1036 | 4-36P | Reel | 1000pcs |

14 | 0.5/1.0 | 2 | Bottom Contact, Front Flip with Lock | EW524/FPC0524 | 4-60P | Reel | 2000pcs |

|

Download catalogues and drawings

Wire to Board Connector

Show some parts of our connectors, more connectors, please contact with us directly.

Pitch: IDC0.6mm

PIN RANGE:2-20pin Housing and Wafer:Right Angle and Vertical type

Pitch: IDC0.8mm

PIN RANGE:2-20PIN Housing and Wafer:Right Angle and Vertical type

Pitch: 1.0mm

Single and Dual Row Terminal, Housing, Wafer:Right Angle and Vertical type;Tin or Golden plate

Pitch: 1.25mm

Pin Range:2-20pin; Housing, Wafer:Right Angle and Vertical type;Tin or Golden plate

Pitch: 2.0mm

Pin Range:2-20pin; Housing, Wafer:Right Angle and Vertical type;Tin or Golden plate

Pitch: 3.0mm

Pin Range:2-20pin;Single and Dual Row Terminal; Housing, Wafer:Right Angle and Vertical type;Tin or Golden plate

Wire to Board Connector Catelogue

Show some parts of our connectors, more connectors, please contact with us directly.

No. | Part No. | Pitch(MM) | Type | Pin Range |

1 | EWWB0600-XXP-HSG | 0.6 | Wire Housing Terminal | 2-20/24p |

2 | EWWB0600-XXP-WR | 0.6 | PCB Wafer right angle | 2-20/24p |

3 | EWWB0800-XXP-HSG | 0.8 | Wire Housing Terminal | 2-20/24p |

4 | EWWB0800-XXP-WR | 0.8 | PCB Wafer right angle | 2-20/24p |

5 | EWWB0800-XXP-WV | 0.8 | PCB Wafer Vertical | 2-20/24p |

6 | EWWB1000 | 1 | Terminal/Housing/Wafer | 2-20pin |

7 | EWWB1250 | 1.25 | Terminal/Housing/Wafer | 2-20pin |

8 | EWWB125000 | 1.25 | Terminal/Housing/Wafer | 2-20pin |

9 | EWWB1500 | 1.5 | Terminal/Housing/Wafer | 2-20pin |

10 | EWWB2000 | 2 | Terminal/Housing/Wafer | 2-20pin |

11 | EWWB2500 | 2.5 | Terminal/Housing/Wafer | 2-20pin |

12 | EWWB3000 | 3 | Terminal/Housing/Wafer | 2-20pin |

Download catalogues and drawings

Customize Service

Customize your connector

On the basis of the existing connector, make some changes to meet your use environment, you can save time and money

Pitch0.5mm to 1.0mm

We have pitch 0.5mm connectors and can use special fixtures to make it to 1.0mm pitch connectors.Just need to make some parts of the mold, itcan quickly meet your needs. Save money and time.

The thickness of FPC/FFC Cable

We only need to make a new set of terminal die, can meet your wire thickness requirements. The standard is 0.2mm or 0.3mm, but there are always some non-standard products.

Contact point of the terminal

Usually, our contact points are single contact points, but the use environment of some electronic products needs to be strengthened and fixed. We can customize some plastic molds or terminal molds according to the customer's environmental assessment.

Do you have any special needs? Do You need to consult our connector?

OEM/ODM Service

What is OEM?

What is OEM?

OEM stands for Original Equipment Manufacturer. It refers to a company that produces parts or equipment that are then marketed by another company under their own branding. Here’s a detailed explanation of what OEM entails:

Key Aspects of 00OEM:

Production and Branding:

- An OEM manufactures products or components that are purchased by another company and retailed under that purchasing company’s brand name. The products are often integrated into a larger system or sold as a component of a finished product.

- For example, a company might produce electronic connectors that are then branded and sold by a larger electronics company under their own brand.

Industry Examples:

- Automotive Industry: An OEM might produce parts like engines, transmissions, or electronic components that are used in vehicles branded and sold by car manufacturers like Ford or Toyota.

- Technology Industry: Companies like Intel or AMD produce processors that are used in computers branded and sold by companies like Dell or HP.

OEM vs. Aftermarket:

- OEM Parts: These are components made by the original manufacturer of the product, designed to fit and function exactly like the original parts. They ensure high quality and compatibility.

- Aftermarket Parts: These are parts made by other manufacturers that can be used as replacements. While often cheaper, they might not always match the quality or specifications of OEM parts.

Benefits of OEM Products:

- Quality Assurance: OEM products are made to the original specifications, ensuring high quality and performance.

- Warranty: OEM parts usually come with a warranty from the original manufacturer, providing additional security.

- Compatibility: OEM products are guaranteed to fit and function with the original equipment, ensuring seamless integration and performance.

Examples of OEM in Technology:

- Microsoft and PC Manufacturers: Microsoft creates operating systems like Windows, which are installed on computers manufactured by companies like Dell or HP. In this scenario, Dell or HP are the OEMs.

- Automotive Sector: Companies like Bosch or Delphi manufacture parts that are used in vehicles produced by companies like Ford or Toyota.

Business Relationships:

- OEM relationships involve detailed agreements and specifications to ensure the produced parts meet the required standards and integrate seamlessly into the final product.

Sinolulu’s OEM Capabilities

At Sinolulu, we have the capability to produce OEM connector products. This means we can manufacture high-quality connectors that can be branded and sold by other companies. Here’s what our OEM process includes:

Custom Product Development:

- Clients provide us with physical samples or specific requirements.

- Our R&D team performs a detailed analysis and dissection of the product.

Design and Precision Engineering:

- We design precise molds and study load balance.

- High-quality steel is selected for mold manufacturing to ensure durability and accuracy.

Advanced Manufacturing Facilities:

- Our factory is equipped with 12 TOYO horizontal injection molding machines and six high-speed stamping machines for metal terminals.

- We have a reputable electroplating facility nearby to ensure timely processing of terminals.

Rigorous Testing and Quality Control:

- We conduct simulated SMT tests to ensure connector performance.

- Our laboratory is equipped with advanced testing equipment, including temperature and humidity test chambers, IR reflow ovens, and more.

Comprehensive QA Processes:

- Adherence to strict inspection standards, including IQC (Incoming Quality Control), IPQC (In-Process Quality Control), FQC (Final Quality Control), and OQC (Outgoing Quality Control).

Professional After-Sales Support:

- A dedicated team to provide customer service and technical support.

- Over 20 years of experience in the electronic connector industry.

By choosing Sinolulu as your OEM partner, you are selecting a reliable product and a dedicated team committed to your success. For any inquiries or to discuss your specific requirements, please feel free to contact us.

Best regards,

Lulu

What is ODM?

What is ODM?

ODM stands for Original Design Manufacturer. It refers to a company that designs and manufactures a product as specified, which is then branded by another firm for sale. Here’s a detailed explanation of what ODM entails:

Key Aspects of ODM:

Design and Manufacturing:

- An ODM is responsible for both the design and the manufacturing of a product. This means they develop the product from concept to final production, following the specifications provided by the client.

- The client then sells the product under their own brand name, often with minimal changes to the original design.

Industry Examples:

- Consumer Electronics: A company might design and produce smartphones or tablets, which are then branded and sold by another company.

- Fashion Industry: ODMs design and manufacture clothing lines that are branded and marketed by fashion retailers.

ODM vs. OEM:

- OEM (Original Equipment Manufacturer): Produces products based on designs provided by the client. The client handles the branding and marketing.

- ODM (Original Design Manufacturer): Designs and manufactures products based on their own or collaboratively developed designs, which are then branded by the client.

Benefits of ODM Products:

- Cost-Effective: Clients can save on R&D costs as the ODM handles the design process.

- Speed to Market: ODMs can help bring products to market more quickly as they have the necessary expertise and production capabilities.

- Innovation: ODMs often bring innovative design ideas and technological advancements, benefiting clients who might lack in-house design capabilities.

Examples of ODM in Technology:

- Consumer Electronics: Companies like Foxconn design and manufacture electronic devices, which are then branded and sold by major tech companies like Apple or Sony.

- Home Appliances: ODMs design and produce appliances such as refrigerators and washing machines, which are branded and sold by companies like LG or Whirlpool.

Business Relationships:

- ODM relationships involve detailed agreements to ensure the design and production meet the client’s standards and specifications.

Sinolulu’s ODM Capabilities

At Sinolulu, we have the capability to produce ODM connector products. This means we can design and manufacture high-quality connectors according to your specifications, which can then be branded and sold under your company’s name. Here’s what our ODM process includes:

Custom Product Development:

- Our R&D team works closely with clients to understand their specific requirements and develop custom designs.

- We provide detailed drawings and prototypes for client approval.

Precision Engineering:

- We utilize advanced CAD/CAM software for precise design and engineering.

- High-quality materials and stringent quality control processes ensure the final product meets all specifications.

Advanced Manufacturing Facilities:

- Our factory is equipped with 12 TOYO horizontal injection molding machines and six high-speed stamping machines for metal terminals.

- A nearby reputable electroplating facility ensures timely processing of terminals.

Rigorous Testing and Quality Control:

- We conduct comprehensive testing, including simulated SMT tests, to ensure connector performance.

- Our laboratory is equipped with advanced testing equipment, including temperature and humidity test chambers, IR reflow ovens, and more.

Comprehensive QA Processes:

- Adherence to strict inspection standards, including IQC (Incoming Quality Control), IPQC (In-Process Quality Control), FQC (Final Quality Control), and OQC (Outgoing Quality Control).

Professional After-Sales Support:

- A dedicated team to provide customer service and technical support.

- Over 20 years of experience in the electronic connector industry.

By choosing Sinolulu as your ODM partner, you are selecting a reliable product and a dedicated team committed to your success. For any inquiries or to discuss your specific requirements, please feel free to contact us.

Best regards,

Lulu

ODM Process

Evaluate, develop and design connectors

Please provide us with the physical connector or drawing you need.

Put the production mold into production

We have precision injection molding machines and high speed metal stamping machines

Make Mold

Usually the mold of the connector includes a plastic mold and a hardware mold

Assembly of connectors

If the demand is large, we will develop automatic assembly machine; If the demand is not large, we can use manual, but to develop manufacturing fixtures to facilitate production.