How to produce a FPC Connector

Welcome to Lulu’s Factory

Lulu will show you around the standard connector factory

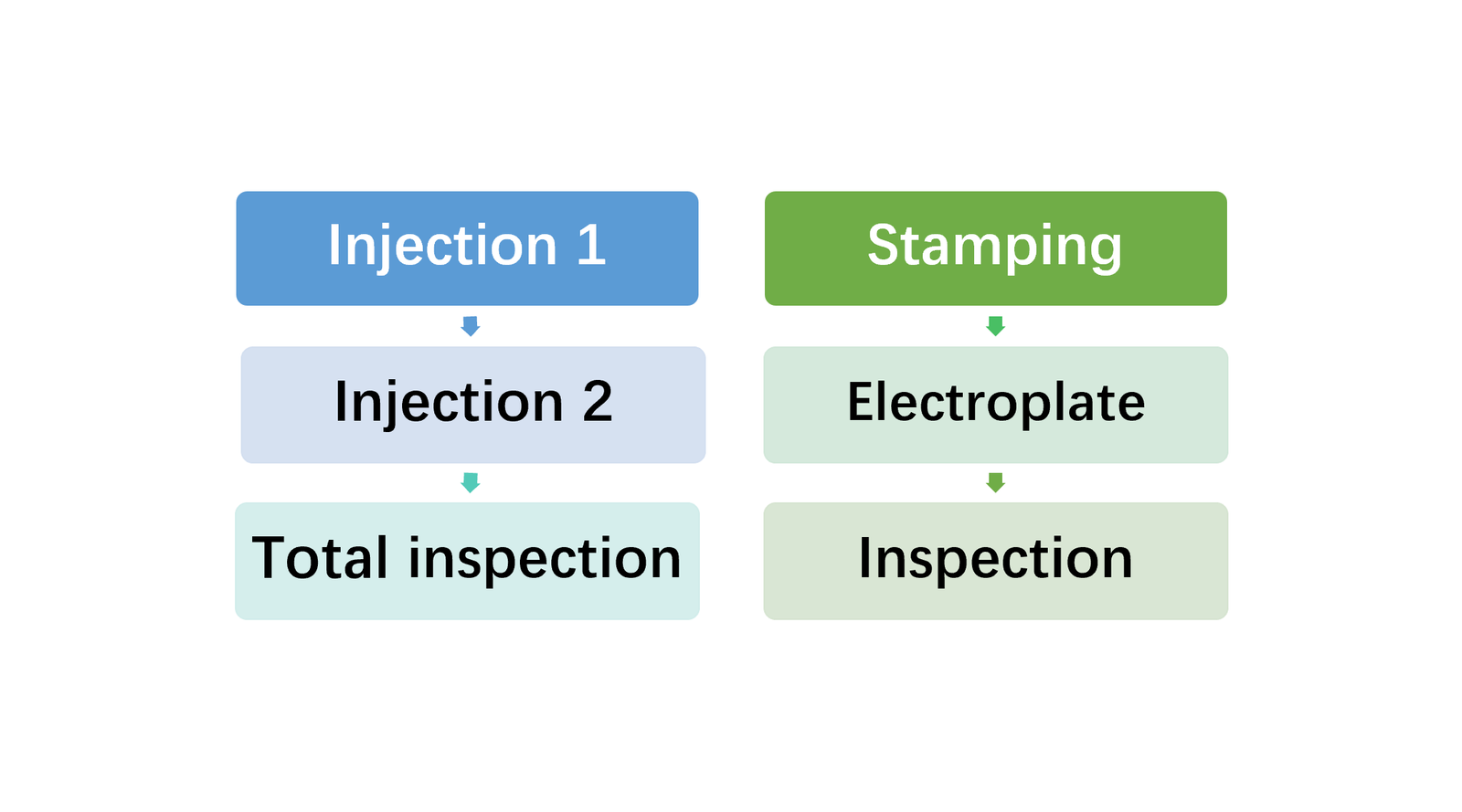

FPC connector is a kind of connector, most of the connectors include precision plastic parts, metal stamping parts, so a standard connector factory should have injection molding machine, stamping workshop, electroplating factory, assembly production line. Let’s have a look at our production facilities first.

How to produce a FPC Connector

Next, we will follow the production steps to introduce the production process and production equipment.

injection moulding

Connectors usually contain plastic parts that are molded by injection molding and put into use.General plastic parts include two parts: the main body and the cover.

- At present, there are 12 sets of 50-ton injection molding machines (TOYO) in our factory.

- Monthly production capacity reaches 20KK

- The precision is 0.01mm

metal stamping

PCB board connector: wire-to-board connector, FPC connector, board-to-board connector. They all include metal parts, usually made of phosphor copper or brass. Press the copper strip into terminals.

electroplate

The metal in the connector is copper, but in order to ensure the stability of the product, it is usually used after electroplating. Electroplating is generally nickel plating first, and then gold plating or tin plating according to the customer’s use environment.

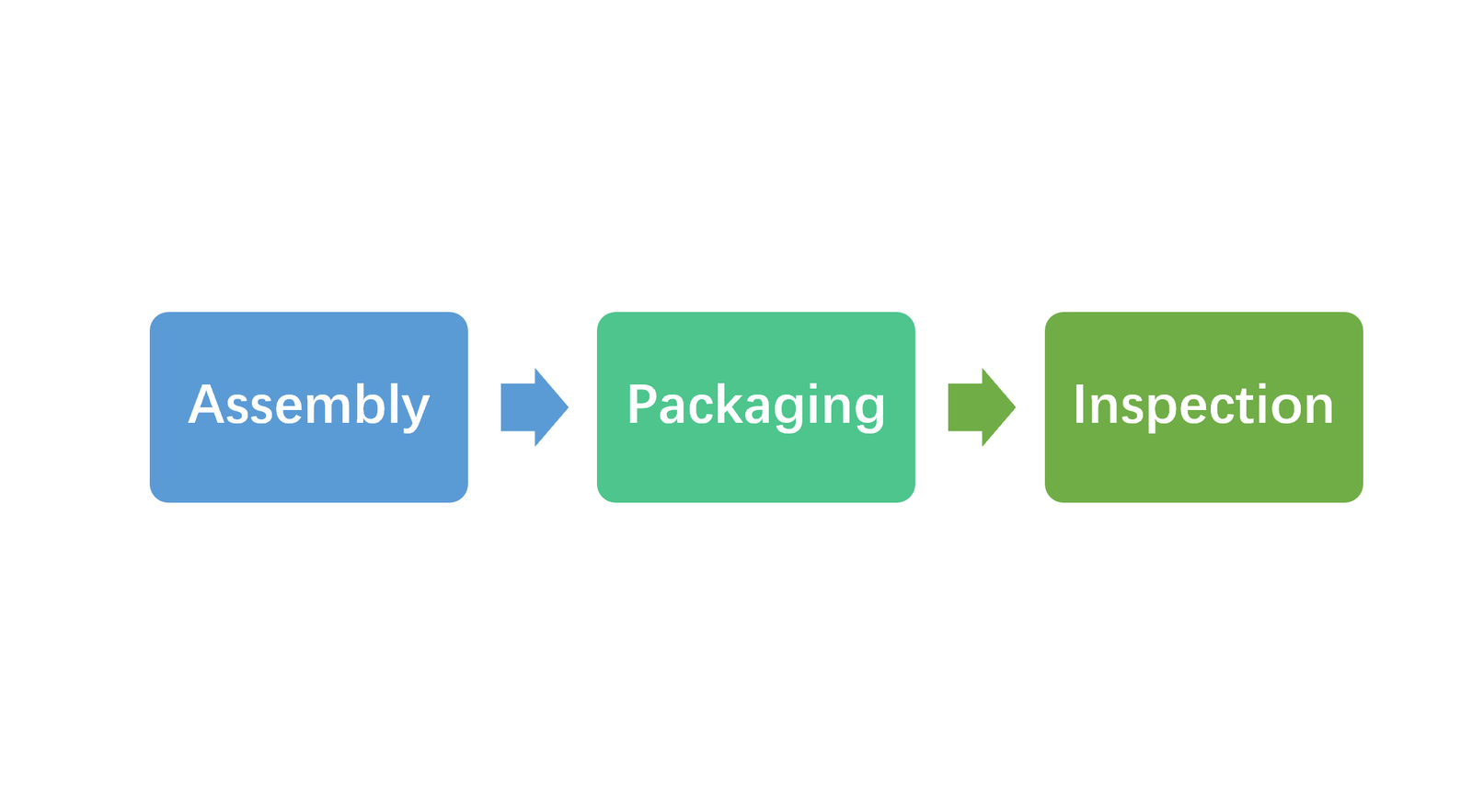

assemble

The injection molding and stamping mentioned earlier are the finished parts for preparing FPC connectors/ wire-to-board connectors/ board-to-board connectors.We use a flexible production plan.

- Small order, manual assembly

- Large orders, with automatic assembly machine

- At present, there are more than 50 automatic assembly machines and more than 10 CCD automatic inspection packaging machines in the factory.

- The monthly production capacity can reach 15KK.

International standard laboratory for connectors

Next

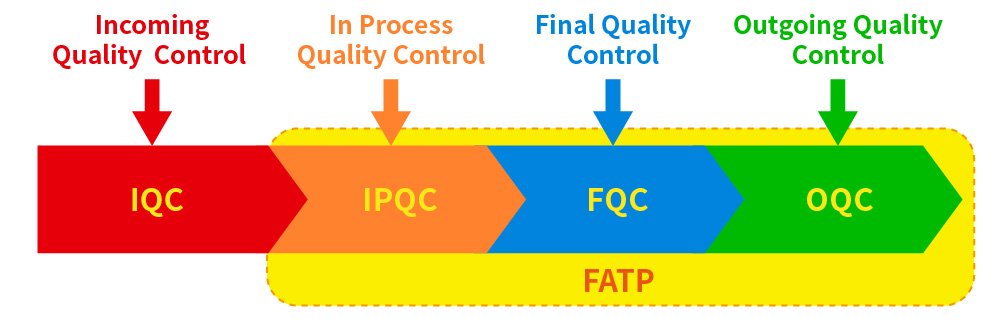

Why does a connector factory need a standard laboratory?

Standard inspection procedures and procedures for connectors

OEM/ODM Featured Production Links

OEM/ODM Service: If the customer needs to customize the connector, it can be fully customized, which needs to spend a lot of money. If we make a small update on our existing connectors, we can also meet. Because we have our own mold maker

If you want to customize a connector, you will be involved in our core technology: Develop plastic mold and automatic assembly machine.

Customize your own Connector

1. Fully develop a connector 2. Turn the existing connector 0.5mm spacing into 1.0mm spacing 3. The current metal terminal contact point, from a single contact to a double contact M, more firm 4. The LOCK connector can be customized according to the FPC/FFC line Lock. And so on...

Learn more interesting production stories,contact us to visit the factory.

Get in touch today and receive a complimentary consultation.