Introduction

In today’s technologically driven world, liquid crystal display (LCD) screens are ubiquitous, found in everything from smartphones to industrial equipment. A critical component that enables the functionality and reliability of these screens is the FPC (Flexible Printed Circuit) connector. This article explores the relationship between LCD screens and FPC connectors, detailing the top LCD manufacturers globally and explaining how FPC connectors are extensively used in LCD screen applications.

Top 20 LCD Manufacturers and Their Locations

Understanding the scale and distribution of LCD manufacturing is essential to appreciating the widespread use of FPC connectors. Here are the top 20 LCD manufacturers and their respective locations:

- BOE Technology Group Co., Ltd. – Beijing, China

- LG Display – Seoul, South Korea

- Samsung Display – Suwon, South Korea

- Innolux Corporation – Miaoli County, Taiwan

- AU Optronics Corp. – Hsinchu, Taiwan

- Sharp Corporation – Sakai, Japan

- Tianma Microelectronics Co., Ltd. – Shenzhen, China

- CSOT (China Star Optoelectronics Technology) – Shenzhen, China

- Japan Display Inc. (JDI) – Tokyo, Japan

- HannStar Display Corporation – Taipei, Taiwan

- CEC Panda LCD Technology Co., Ltd. – Nanjing, China

- Visionox – Kunshan, China

- KONKA Group Co., Ltd. – Shenzhen, China

- Everdisplay Optronics (EDO) – Shanghai, China

- CEC Huaxing Optoelectronics Technology – Shenzhen, China

- Royole Corporation – Shenzhen, China

- HKC Corporation Limited – Shenzhen, China

- Truly International Holdings Limited – Guangdong, China

- Varitronix International Limited – Hong Kong, China

- Kyocera Corporation – Kyoto, Japan

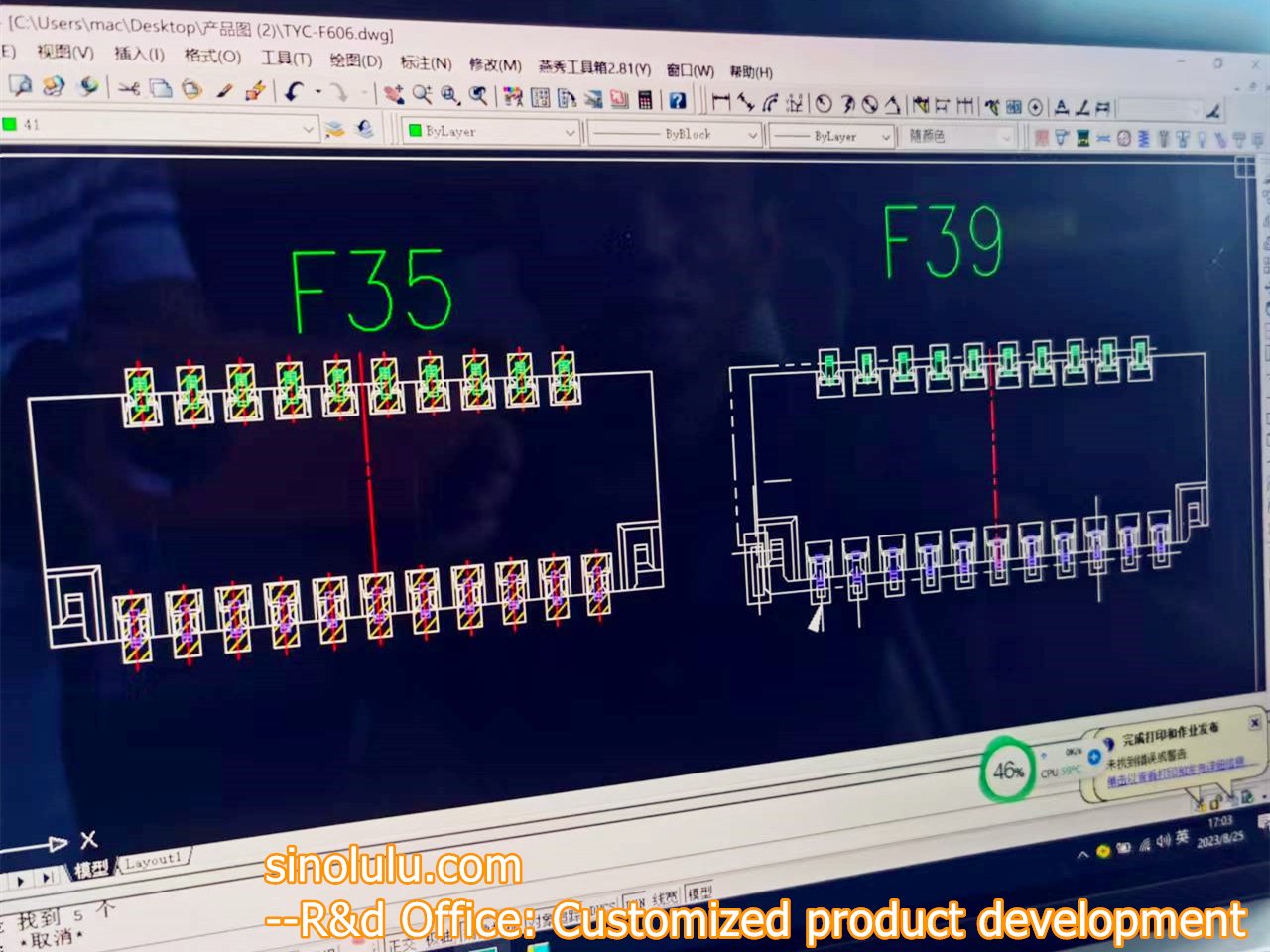

FPC Connectors in LCD Screen Applications

FPC connectors are crucial in various components of LCD screens, including:

- Driver Boards:

- Function: Driver boards control the pixels of the LCD, managing the display of images and text. They require reliable connections to the main board, where FPC connectors come into play.

- Usage: FPC connectors are used to connect the flexible circuit of the LCD panel to the rigid PCB of the driver board, ensuring a stable and secure connection.

- Adapter Boards:

- Function: Adapter boards translate signals from the main device to the format required by the LCD screen.

- Usage: FPC connectors allow these boards to connect flexibly to various components within a confined space, facilitating easy assembly and maintenance.

- Touch Panels:

- Function: Touch panels overlay the LCD screen, allowing user interaction through touch input.

- Usage: FPC connectors are used to connect the touch sensor to the display and the control board, ensuring smooth signal transmission and responsive touch functionality.

Impact of High LCD Production on FPC Connector Demand

The massive production of LCD screens globally has led to a significant increase in the demand for FPC connectors. Here are a few reasons for this trend:

- High Volume Production: With companies like BOE and LG Display leading the charge in LCD production, the sheer volume of screens produced necessitates a large number of FPC connectors.

- Diverse Applications: The wide range of applications for LCD screens—from consumer electronics to automotive displays—requires FPC connectors in various configurations and specifications.

- Technological Advancements: As LCD technology advances, the need for more sophisticated and reliable FPC connectors grows, driving innovation and demand in the connector market.

Conclusion

FPC connectors play an indispensable role in the functionality and reliability of LCD screens. The top LCD manufacturers, spread across Asia, rely heavily on these connectors to ensure their products meet the high standards expected in the market. The ongoing proliferation of LCD technology across multiple industries only underscores the critical importance of FPC connectors in modern electronics.

By understanding the extensive use and critical function of FPC connectors, one can appreciate their significance in the advancement and integration of LCD technology in our daily lives.