Understanding FPC Connectors: An Essential Component in Modern Electronics

Flexible Printed Circuit (FPC) connectors are integral components in contemporary electronics, widely used for their versatility, compact size, and reliability. This article aims to elucidate what FPC connectors are, their primary applications, their functions, and the various types available in the market.

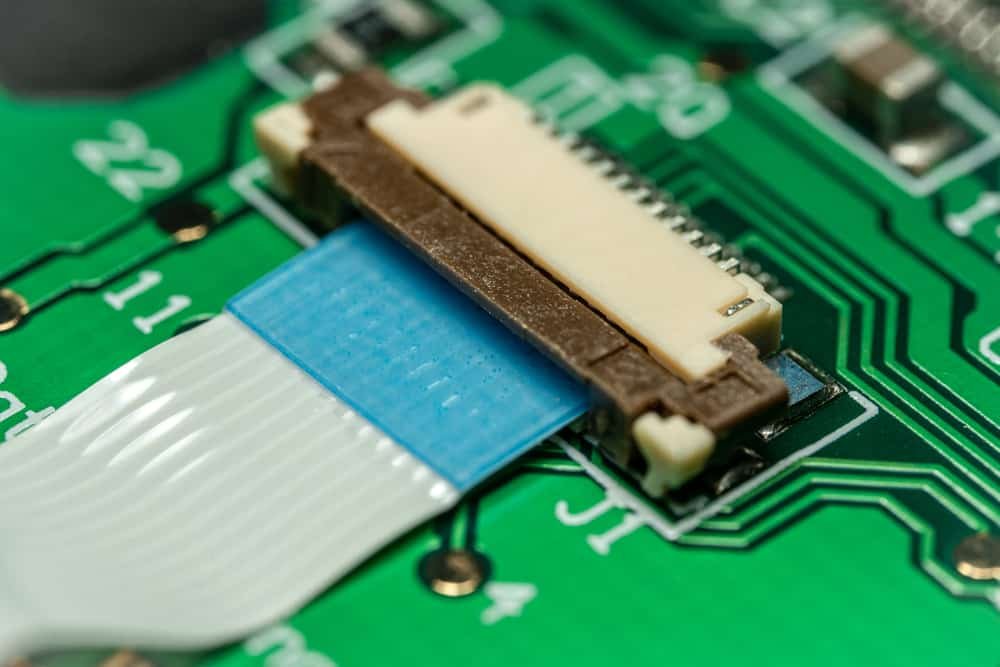

What is an FPC Connector?

An FPC connector is a type of connector used to connect flexible printed circuits to other electronic components. These connectors are designed to accommodate the unique properties of FPCs, which are made from thin, flexible materials that allow for the creation of highly compact and versatile electronic assemblies. FPC connectors provide a secure and efficient way to connect these flexible circuits to rigid boards or other components.

Main Applications of FPC Connectors

FPC connectors are used across a wide range of electronic products due to their flexibility and compact size. Some of the primary applications include:

- Consumer Electronics:

- Smartphones and Tablets: Connecting screens, cameras, and other modules to the mainboard.

- Wearable Devices: Used in smartwatches and fitness trackers to connect various sensors and displays.

- Automotive Electronics:

- Dashboard Displays and Infotainment Systems: Connecting displays and control units within the car.

- Rearview Cameras and Sensors: Ensuring reliable connections in automotive safety systems.

- Medical Devices:

- Portable Medical Monitors: Connecting displays and control modules in devices like glucose monitors and portable ECG machines.

- Imaging Equipment: Used in ultrasound and other diagnostic equipment.

- Industrial Equipment:

- Human-Machine Interfaces (HMIs): Connecting touchscreens and control units in industrial control panels.

- Robotics: Used in robotic arms and automated systems to connect sensors and actuators.

- Home Appliances:

- Smart Home Devices: Connecting various modules in smart locks, thermostats, and other home automation products.

- Kitchen Appliances: Used in modern appliances with touchscreens and advanced control systems.

Functions of FPC Connectors

FPC connectors serve several crucial functions in electronic devices:

- Space-Saving: Their compact design allows for more efficient use of space within devices.

- Flexibility: They can bend and fold, which is essential in devices where space is limited and components need to be packed tightly.

- Reliability: Provide a stable and secure connection, essential for the proper functioning of electronic devices.

- Ease of Installation: Designed for easy attachment and detachment, facilitating assembly and maintenance.

Types of FPC Connectors

There are several types of FPC connectors, each designed to meet specific needs and applications:

- ZIF (Zero Insertion Force) Connectors: These connectors allow the FPC to be inserted with minimal force, reducing the risk of damage during installation.

- Non-ZIF Connectors: Require more force to insert the FPC but offer a secure connection once installed.

- Slider Connectors: Feature a sliding mechanism to secure the FPC, combining ease of use with a reliable connection.

- Flip-Lock Connectors: Have a flip-lock mechanism that secures the FPC in place, ensuring a strong connection even in high-vibration environments.

Conclusion

FPC connectors play a vital role in modern electronics, enabling the creation of compact, reliable, and flexible electronic assemblies. Their widespread use in consumer electronics, automotive systems, medical devices, industrial equipment, and home appliances underscores their importance in today’s technology landscape. Understanding the different types of FPC connectors and their applications can help in selecting the right connector for specific needs, ensuring optimal performance and reliability.

By comprehensively understanding the various aspects of FPC connectors, one can appreciate their significance in the advancement of modern electronics.